Calcium Silicate Special & Drymix-Special

WKB Systems GmbH, 48477 Hörstel, Germany

Automatisation of production lines with innovative solutions

Loading...There is no doubt that the production process automatisation supplies the manufacturer with a wide range of advantages to survive on the market: upgraded product quality, enlarged product portfolio, optimised production costs and improved productivity level. These are the key factors to achieve customers satisfaction and to run a profitable and efficient production line.

Taking into consideration the automatisation of a sand lime brick plant it is to admit that there are some major production areas that can be automated: raw materials processing, hardening carriage cleaning, complete plant logistics and packing line area.

Precise dosing and fine mixing

The complete equipment of the raw material processing section is of utmost importance for the production of sand lime bricks with perfect quality characteristics, such es even strengths and smooth surface profiles. Thanks to the controlled weighing and mixing technology of WKB it is possible to manufacture a wide range of sand lime products (incl. hollow and colored bricks) exactly according to the provided recipes. This production area is equipped with all the needed soft and hardware tools for a smooth production in a fully automated way.

Smart cleaning of the carriage surface

The sticking of material on the surface of a hardening carriage is a well-known issue in the production of sand lime products. It usually results in a very poor product quality and some decreases in the production output as the end product is damaged or scratched.

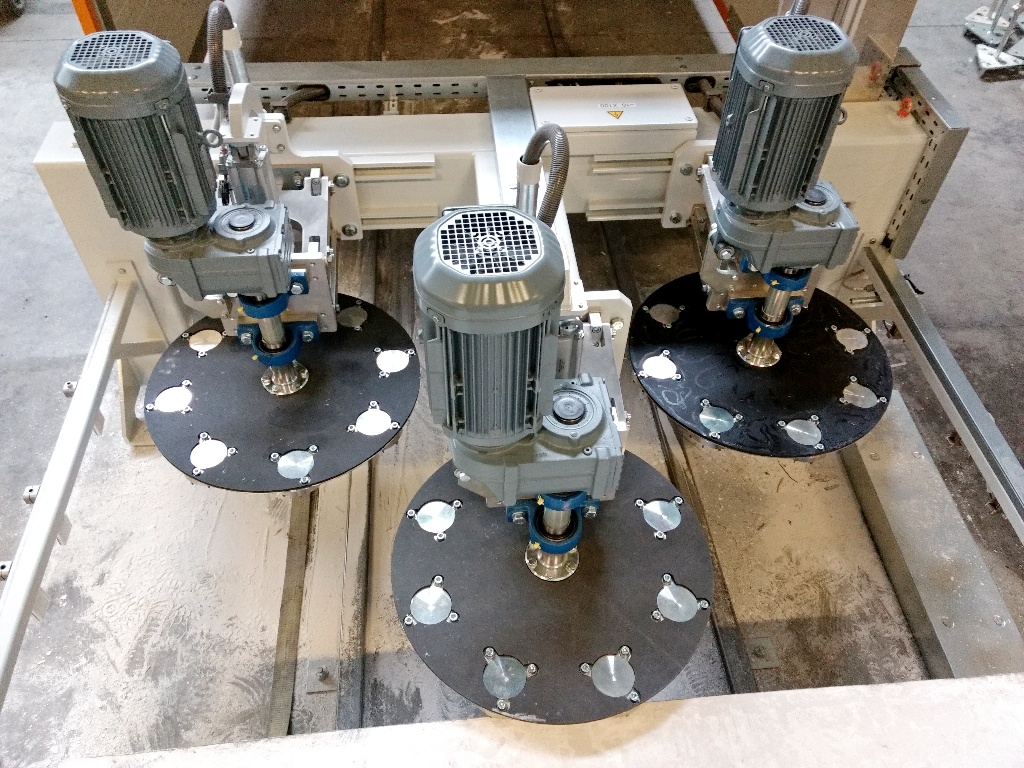

In order to eliminate this problem, the experts of WKB Systems developed a very smart cleaning station for hardening carriages that operates in a fully automated mode but the speed of a cleaning process can be adjusted via potentiometer.

This precise cleaning device is always adopted to the size of customer’s carriages and equipped with the latest technology. The core component of the station is a group of three rotating disks with integrated blades. Once the carriage is underneath the cleaning station, two disks start to rotate and are lowered electrically or pneumatically by a light barrier. Another light barrier activates the third disk as far as the carriage moves forward. The roughing or finishing blades remove the mass sticking from the surface of the carriage and flatten it in a proper way. After the process is finished, the disks with blades are lifted and the cleaned carriage is forwarded with a pushing mechanism to the area of a sand lime bricks press. At the next step the carriage is loaded with freshly pressed, so-called “green” bricks. The perfectly cleaned surface of the carriage ensures high quality of the end product during handling, autoclaving and packing processes.

Hardening carriages circulation – optimised production flow

The completely automated production process in a sand lime brick plant can be achieved to a large extent thanks to the special system called “hardening carriages circulation” that was developed by WKB engineers. This system is based on the concept of a completely synchronised plant logistics.

It comprises the usage of traversers and some additional facilities such as tackle systems, pushing mechanisms, transport devices, electric control systems with product tracking, etc.

The cycle starts as the first traverser is loaded with up to two cleaned hardening carriages by a pushing mechanism and forwards them to the area of a sand lime brick press. Here the carriages are then transported with the pushing mechanism directly to the press to be stacked with “green” bricks.

Once the bricks have been pressed a special gripper removes them from the press to place on a hardening carriage. The loaded carriage is picked up from the press rail with a pushing mechanism of the second traverser. This traverser is able to transport up to 6 carriages at a time. It forwards the whole load to the autoclaving area and charges the autoclaves.

After the finished autoclaving process the autoclaves are unloaded with the third traverser that forwards sand lime bricks to the packing area. Depending on the plant structure the third traverser can be equipped with a pushing mechanism or a so-called locomotive. In the packing area the bricks are picked up with a manipulator or a special gripper and empty carriages are forwarded to the cleaning station. At the next step the first traverser takes cleaned carriages to be transported to the press. So, the next cycle of the hardening carriage circulation starts.

High efficiency in the packing area

It is of great importance to organise all the flows in the packing area in the most efficient way in order to achieve the highest profit margin ratio of a production line.

There is a large variety of possibilities how to arrange the packing process in a sand lime brick plant. It primarily depends on the area available, the product range and a level of the automatsation needed.

It usually starts as the loaded carriages with bricks are forwarded with a traverser to the packing area. Here the pushing mechanism of the traverser transports carriages on packing rails. Then the carriages move one after another through a special portal gripping facility that pushes the bricks together in order to eliminate the spaces between them. The same or another portal gripping facility takes the bricks and places them on a wooden pallet.

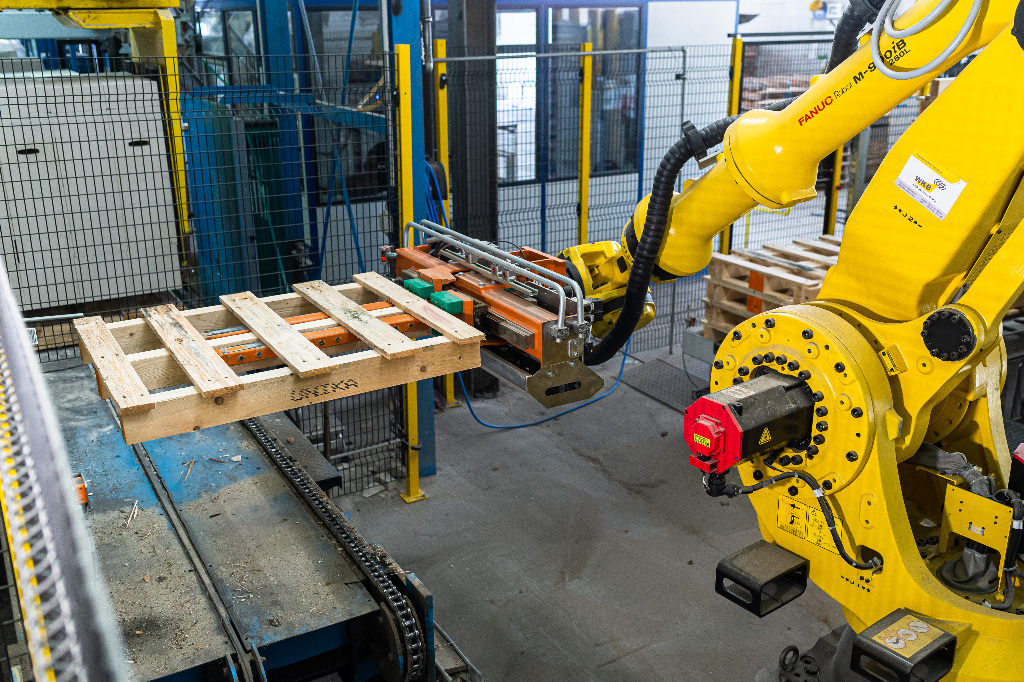

The engineers of WKB Systems often advise to use an industrial robot in the packing area in order to improve all the processes with respect to speed, quality, highest precision and plannability. Thanks to its flexibility the robot with a special gripper can handle not only bricks of different sizes and formats but also many different types of pallets.

In case of production of a wide range of sand lime products there is no need to stop and retool the packing area to pack format-dependent packages. The robot can be programmed in a such way that it takes the bricks according to a certain stacking plan. As far as there is a surplus of bricks occurs while production of a new format started, this surplus is placed with the robot on a special storage table. When the format is changed again, the surplus is fed back with the robot into the packing process. In such a way any manual intervention with time delays and output reductions during format change is reduced to a minimum.

The robot is also able to form customised packages of a particular height and number of bricks. According to the stacking patterns programmed beforehand it sorts the bricks with the help of a storage area and forms the package sizes needed.

Sometimes bricks are placed on a carriage after being pressed in a form of a crone. These crones must be de-stacked before packing process and it is usually made manually. In order to make the process of de-staking more efficient the robot can be also used.

One another important facility in the packing area is a pallet magazine. It is used for the pallet supply in a completely automated way. The magazine is loaded via roller conveyor with a batch of non-interlaced pallets. As far as one pallet is needed the lowest one is discharged and forwarded with a chain conveyor to the loading area.

A smooth packing process is also guaranteed with the usage of a large variety of chain and roll conveyors, tackle systems and pushing mechanisms.

Strong record of competences and extensive know-how

Thanks to their broad international experience in the production of sand lime bricks the engineers of WKB are able to apply innovative solutions and state-of-the-art technology while realising automatisation projects. Furthermore, having a direct access to the plants all over the world they are aware of all the requirements of modern production lines. It gives WKB specialists the necessary insights to test and adopt any new application to the given external conditions in order to achieve all the goals set by the customer.