Calcium Silicate Special & Drymix-Special

WKB Systems GmbH, 48477 Hörstel, Germany

Format-dependent packet assembling – smart solution for more sustainability

Loading...A German manufacturer with more than 55 years history of sand lime brick production modernised the packaging area of its plant. With a wide range of sand lime products and an annual output of up to 50 million bricks (71 x 115 x 240 mm) the highest priority is given to the sustainability of the production process.

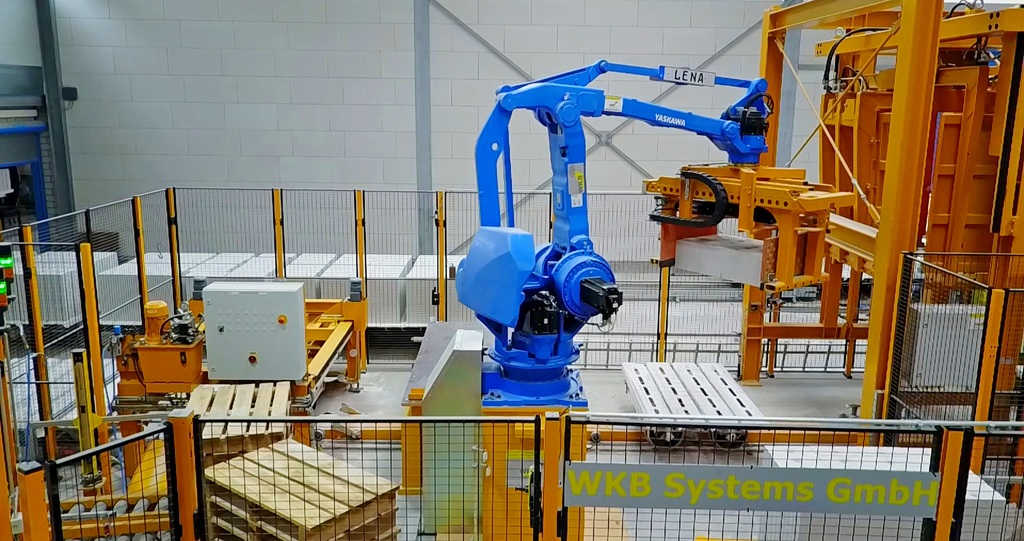

The automatisation of the packaging area was realised by a German manufacturer of state-of-the-art solutions for the building materials industry – WKB Systems GmbH. The project started with thorough investigations on the current situation at customer’s production site. Based on the analysis results the experts of WKB Systems advised on complete modernisation of the packaging area as all the processes here were carried out manually.

Alongside with the automatisation concept the experts of WKB Systems worked out an advanced solution to assemble format-dependent packets of sand lime bricks in a completely automated way. The operational capacity of the line is approx. 50 packets per hour. The packet height varies from 490 to 1250 mm. The max. weight of the packet is 1500 kg. The operation cycle per packet is approx. 72 seconds.

Industrial robot application for more efficiency

While searching for the right solution to satisfy all the requirements of the customer the engineers of WKB Systems relied on the advantages of an industrial robot. Thanks to its high flexibility the robot provides not only ongoing operation mode but also optimises the production process with respect to the speed, quantity and quality combined with measurability, plannability and the highest movements accuracy. These all were the reasons to integrate the industrial robot into the packaging area of the customer’s sand lime brick plant.

Robot gripper of special construction

In order to even strengthen the flexibility of the industrial robot, the engineers of WKB Systems developed a special gripper to manipulate not only sand lime products but also wooden pallets of different types.

The significantly greater dynamics and range of the robot compared to manual operation can also mean that several work steps could be combined. So, the 100% flexibility and system efficiency were fully exploited.

Proper preparation for the next production step

In order to prepare the bricks for picking up by the robot gripper the production-related gaps between brick raws must be eliminated. For this purpose, the experts of WKB Systems made use of an upstream package compactor with an own hydraulic power unit. This special device pushes together the sand lime bricks on the hardening carriage on four sides. The hardening carriage is forwarded through the compactor with a pushing mechanism. As a result, the load of sand lime bricks on a hardening carriage is ready for the next production step - packet assembling.

Format-dependent packet assembling

One of the challenges was the possibility to assemble packets of bricks of a particular format with no manual intervention due to any format change. To solve this quite a complicated issue the robot was programmed to pick up raws of sand lime bricks according to a predefined stacking scheme and to place them on an empty pallet. In case of format-dependent packaging a surplus of bricks often occurs. Nevertheless, it is important to ensure a continuous and smooth packaging process. So, the automated assembling process is ensured as the surplus bricks are temporary stored in a buffer area. When the format is changed again, the surplus bricks are fed back from the buffer area into the packet assembling process. The main advantages of this concept are the ongoing packaging process and the constant productivity level.

The complete transport facilities in the packing area such as chain conveyors, a roller lifting table, roller conveyors, tact pushers, etc. are of scope of supply by WKB Systems GmbH.

Transport safety ensured

Finally, the palletised shipping packages are forwarded through the strapping machines. The vertical and horizontal strapping hoops are provided in a completely automated way to give the brick package transport safety. As weather protection, a stretch hood is used, providing the package with additional stability.

See here a video of the automatisation of the packaging area. Simply scan the QR-code with your smart phone.

Hinweis auf WKB-Company Channel