ARTICLE

Hybrid building system

Designing with BCE – Block Composed Elements

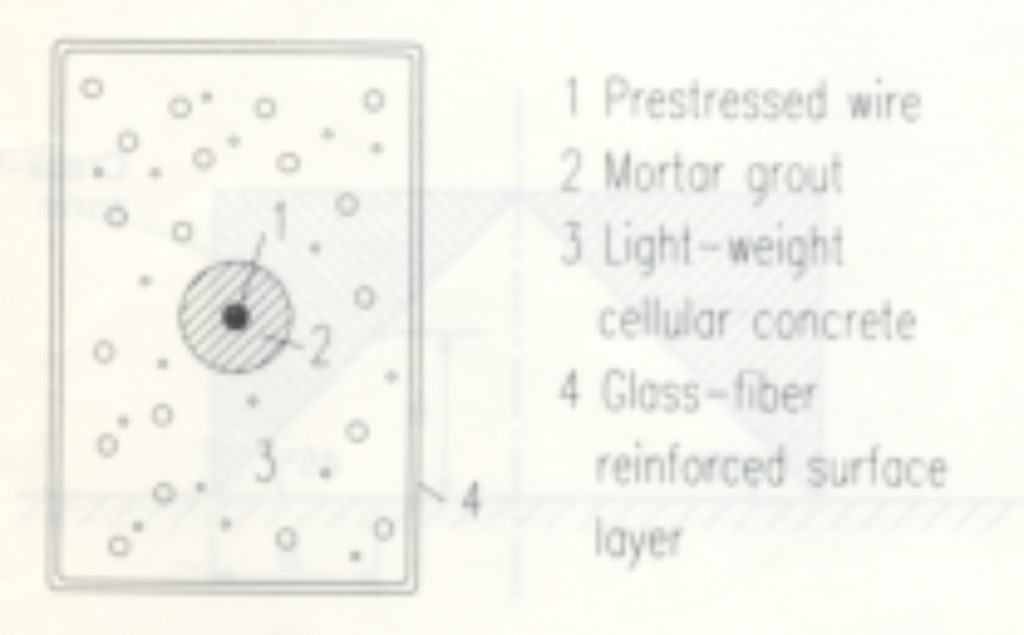

BCE (block composed elements) is a system for advancing a block production into a full panel range based on AAC in combination with HPC (high performance concrete) under mutual prestressing. The condition for this is that all materials have strength capacity to contribute, with limited shrink and creep. The important creep factor was discussed in another paper, ”Aspects on creep of AAC” [3].

The BCE system replaces the integration of a reinforcement line into a block producing facility, which is rather costly and production disturbing. The alternative, a BCE line, can be built alongside an undisturbed block production and finally be taken into swing from one day to the other. The blocks needed for BCE can be taken from any production line, including ash-based material. With ash the hybrid is an example of combining a dominating material, based on industrial waste, with a minor contribution of a premium concrete into high-level products.

Structural panels and beams

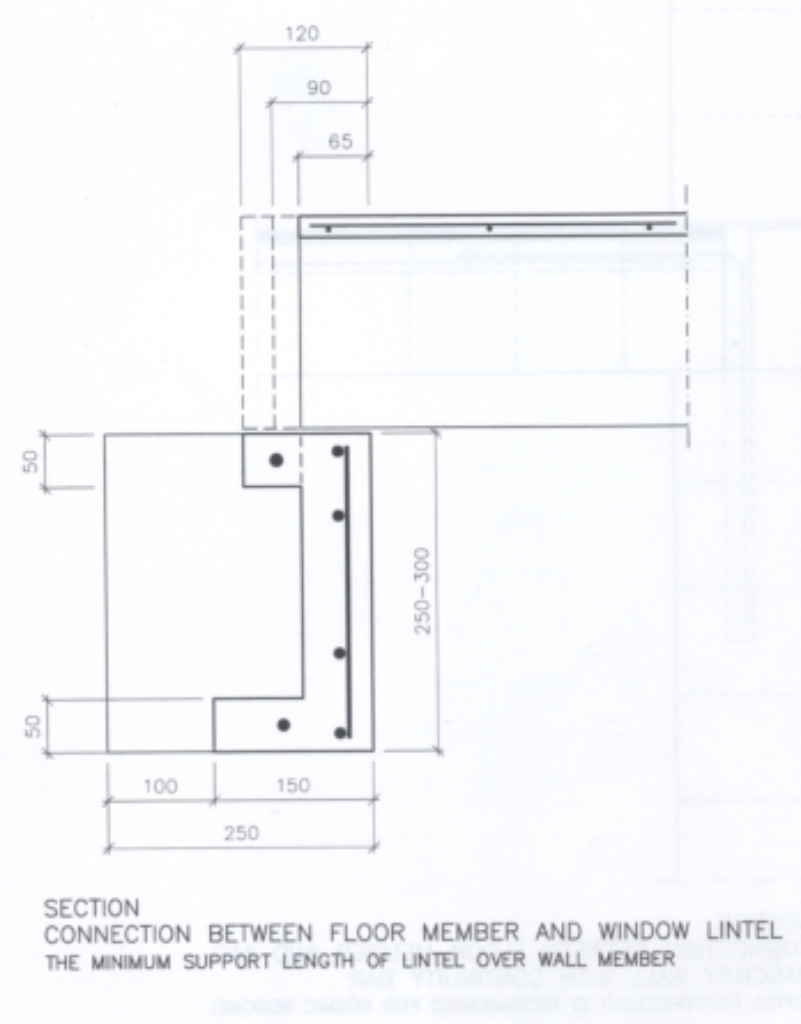

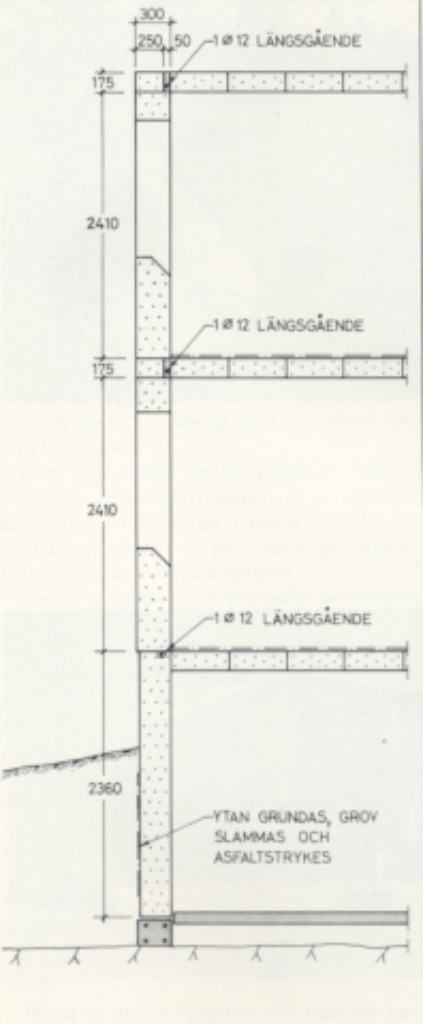

In the previous paper [1] examples of different components for housing construction, floor or roof panels as well as wall panels, were introduced. They were all made of AAC blocks, precisely cut, put together by prestressing carried by a combination of AAC and HPC. AAC is by far the dominating material in volume, whereas HPC is a supplementary muscle to the hybrid. The BCE panels have significant capacity, exceeding by far the capacity of ordinary AAC panels. Also, joints were shown, either for load-bearing façade or for inner-walls carrying floor or roof loads from one or both sides. These components constitute basic elements of a building system. It must be supplemented with prestressed and load-bearing beams and unreinforced parapet block members.

Beams in traditional AAC technology include unstressed reinforcement arranged in a way that copies the ordinary reinforcement of a concrete beam to which extra steel is added on the compressed side. So, the AAC material plays no other role than embedding the internal steel-truss, protecting it from fire hazards. Yet, the torsional stiffness is low, which is unfortunate as beams are normally subject to eccentric loading from supported floor panels. The possibility to wind a thin steel wire around the reinforcement case is used on occasions in order to increase the torsional stiffness but only with great effort.

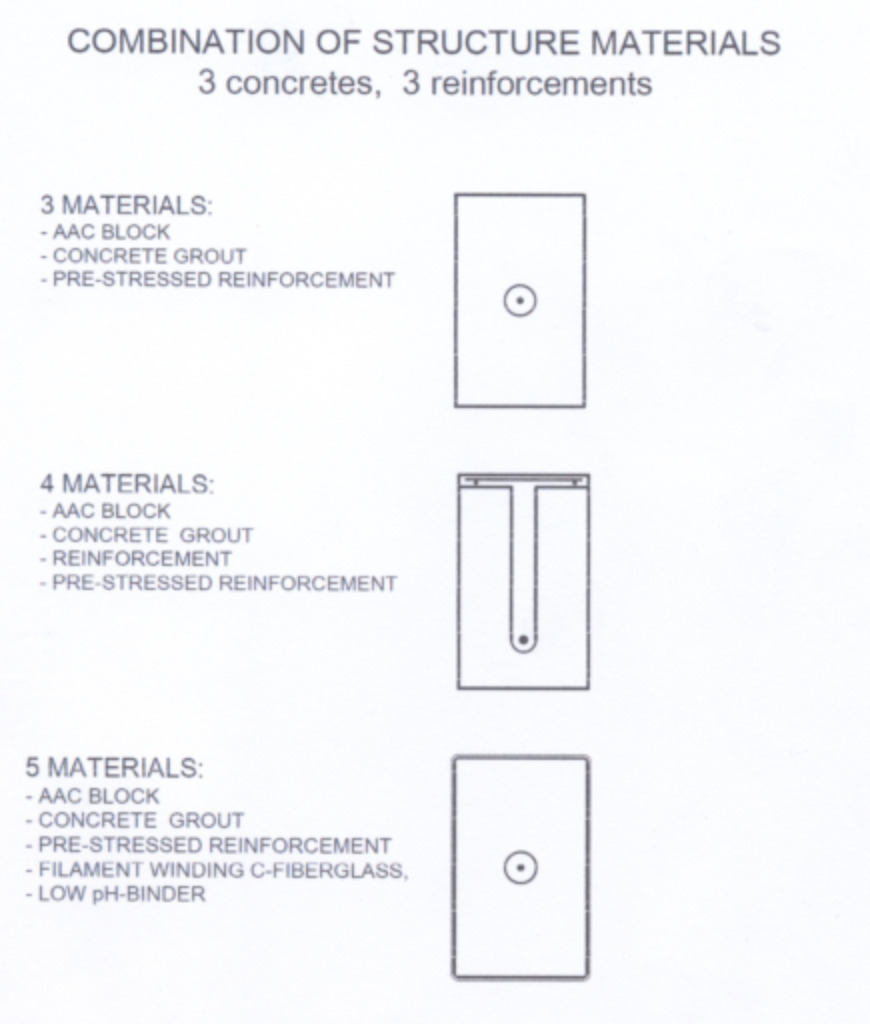

Within the BCE technology, the solution is radically different. There are two possibilities, both prestressed, which helps keeping the structure uncracked under service load. This contributes to durability and reduces deformation.

1) A prestressed hybrid in line with other BCE components – this has an equally low torsional stiffness and can only be applied in case the torque or the span is relatively small.

Objections against the poor torsional stiffness of this solution were met with a more sophisticated alternative:

2) A prestressed hybrid of a different build-up with five materials, with rectangular shape and wrapped with fiberglass in filament winding implying a high torsional stiffness, [4]. The bending stiffness is well included in this product.

This solution was used to establish a full pillar-beam system, introduced in the 1990s, [5]. It included specifications of a production facility. Full hybrids were produced and tested, [6]. The market then was not ready, however, for an alternative to wood, which is always surrounded by a romantic attitude. Our response then was to combine BCE for structural purposes with wood for visual surfaces, to maintain the flair but to no avail. I am confident that time will come for a distinction between materials, which will open the path for AAC in qualified use. This is already obvious in for instance India, [7].

True, hybrid structures are somewhat heavier than plain AAC components because concrete has been added. In housing it means that density is raised by up to 30%, from 500 to some 650 kg/m3. Steel, stressed or unstressed, contributes by less than 2%. The conclusion is that it is still a light building system, with a formal density of less than 30% of massive concrete, or 50% of a hollow core system. It resembles the condition of a wooden structure, which in high-rise structures is sensitive to horizontal loads from wind. This is the case also for BCE, which limits the number of storeys under practical conditions to six.

The load-bearing capacity of BCE is also limited to six storeys in practice, which is apparent from the increase of strength, going from a homogeneous AAC wall of 150 mm to a BCE wall of 120 mm AAC + 30 mm HPC. The relation of compressive strengths of the two concretes is around seven (7). Assuming that HPC is solely responsible for load-bearing at the bottom, the capacity relation becomes 7/5 = 1.4. But the strength of the AAC wall must be reduced due to slenderness, whereas the hybrid maintains full capacity, c.f. [1], which increases the relation between the alternatives to 1.4/0.7 = 2.0. It is well-known that AAC can build a three-storey house – it is obvious that a BCE house can reach the double, i.e. six storeys. Not considering the reduction of live loads with increasing number gives extra security. Calculations of stresses at the bottom of load-bearing facades and interior walls confirm this statement. With appropriate limitations of openings, it is possible to use 9 m spans for floor and roof panels. Limiting to traditional 6 m there is plenty of capacity for increasing the permanent floor load in the interest of acoustic insulation.

Discussion

AAC is a material of great merit in itself. Not only has it strength capacity but also moisture reaction and serves as heat insulator. It can be made from any silicious source, such as natural sand or ash from coal-fed utility plants. The latter is a highly contemporary industrial waste, upgraded to high-level material by the AAC process. It is used for blocks, which in practice extends the masonry culture, dominating the building industry for more than a century. Already in the early 1930s it was applied for reinforced panel production (Siporex), a first step towards composite products made of AAC and steel. Yxhult soon responded with an equivalent panel production. Competition between producers has inspired a refinement of the reinforcement technology up to present standard level.

BCE is in fact a continuation of the reinforcement technology, combining with more materials into sophisticated products to meet qualified requirements. A floor panel contains four materials, two different concretes and two kinds of steel, one for prestressing, the other for resisting limited tensile stresses. To go to five materials, as with the pillar-beam system, may sound complicated but is nothing compared to other everyday products like a smart-phone.

References

[1] Hellers, B G ”The capacity of BCE – a step forward for AAC”, AAC Worldwide 4/2019

[2] http://urn.kb.se/resolve?urn=urn:nbn:se:kth:diva-220883, 2018

[3] Hellers, B G ”Aspects on creep of AAC”, AAC Worldwide 2/2019

[4] Hellers B G & Lundvall O ”Light and strong as wood: the development of hybrid concrete members”, RILEM Materials and Structures, 1995, 28, 479

[5] Bagheri, H ”Kompositer i småhus – Ett byggnadssystem”, Report 47, ISRN KTH/KLA/R—47—SE, ISSN 1101-9468

[6] Hellers B G ”Hybrid concrete beam – Single or double-reinforced hybrid beams of concrete and light-weight concrete in prestressed integration”, ISRN KTH/KLA/R –43—SE, ISSN 1101-9468

[7] Fam A, Schnerch, D & Rizkalla, S ”Rectangular Filament-Wound GFRP Tubes Filled with Concrete under Flexural and Axial Loading”: Experimental Investigation, 2005

With decades of experience and sales in over 100 different AAC plants in 20 countries on 6 different continents, Aircrete Europe is a recognized global leading developer and manufacturer of Autoclaved Aerated Concrete (AAC) machinery and technology for the production of AAC panels and blocks.

Aircrete Europe designs and delivers highly innovative turn-key AAC plants and cutting-edge plant technology. Being the long-term, exclusive project partner for its customers, Aircrete Europe guides you through all the steps of planning, building and operating your AAC factory. Aircrete Europe is a full technology partner, not just a machine supplier, resulting in maximum value creation for its customers.

This AIRCRETE EUROPE channel and all information presented here is provided by AAC Worldwide - the journal for the Autoclaved Aerated Concrete industry. All articles about AIRCRETE EUROPE are available for free. Feel free to share information from this website with other industry professionals!

Aircrete Europe

Zutphenstraat 6

7575 EJ Oldenzaal

The Netherlands

T: +31 54 157 1020

info@aircrete.com

www.aircrete.com