ARTICLE

Aircrete Europe, 7575 ED Oldenzaal, The Netherlands

BIM integrated in AAC project management services

Previously, a traditional multidisciplinary engineering project was based on a set of documents, mostly in the format of drawings and reports. Even when created digitally through Computer-Aided Design (CAD), the project resulted in a package of non-centralized information, creating room for conflict and data redundancy.

Building Information Modeling is an evolved process that contains a great deal of information, going beyond the basic model of CAD. It presents the relevant data necessary for the planning and execution of the project and allows for the project team to collaborate. All the above assists in running an efficient project management in general. BIM is used to identify opportunities for improvement via an intelligent digital approach, in which all project information is integrated in a single location. The models are developed in digital databases that allow for collaboration and information exchange among stakeholders.

Integration of BIM in Aircrete’s projects

Working with several partners (suppliers, customer, local contractors) on multidisciplinary projects, with a growing demand for improvement of information flow, Aircrete Europe incorporates BIM to optimize its solutions and enhance the success of the projects. Currently, Building Information Modeling is being integrated in Aircrete projects by using a BIM environment with a set of software tools and a 3D plant scanner.

The 3D plant scanner captures a high-density point cloud of a physical building, existing equipment and installed utilities. On average, it takes 2 to 3 days and 700 scanned points for the total existing factory hall’s scan to be realized (Fig. 1).

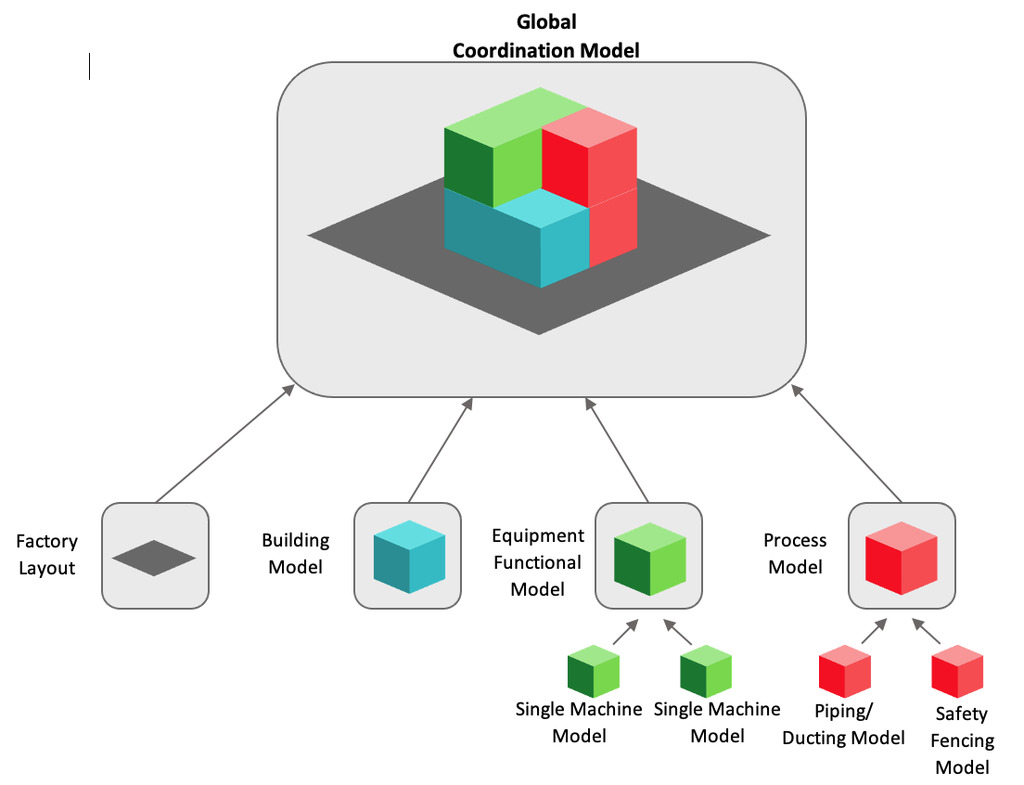

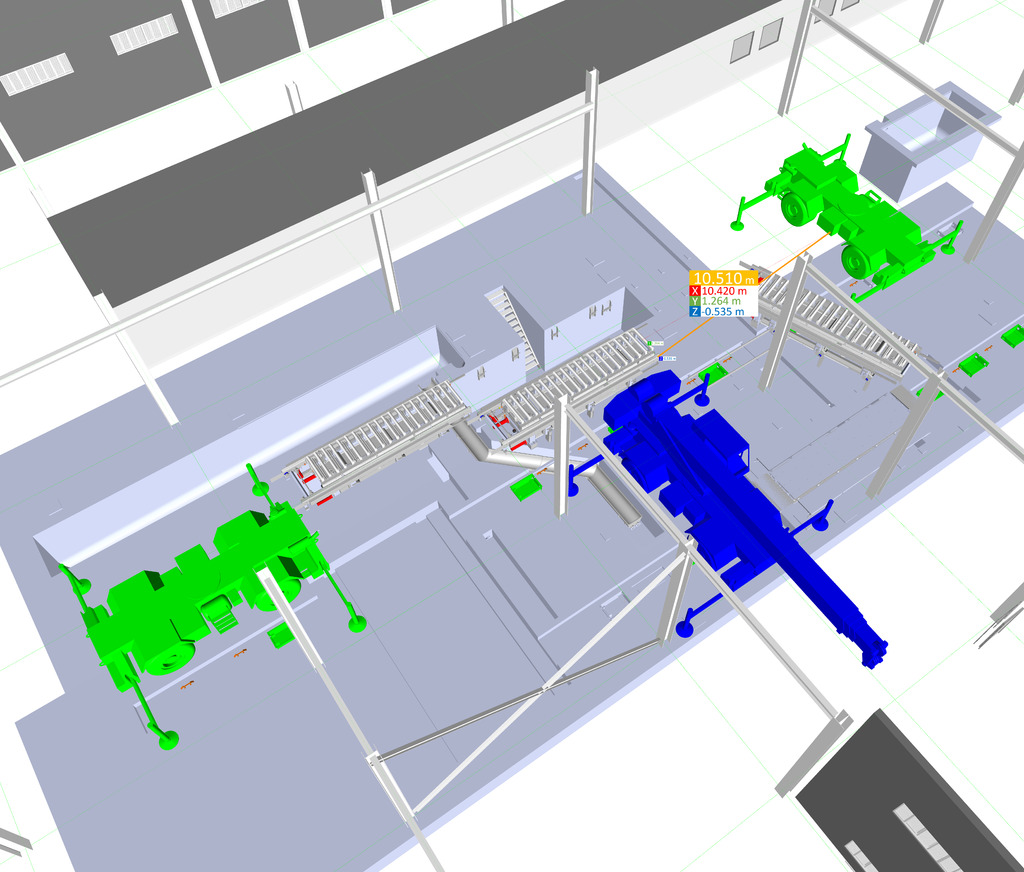

From that, a personalized plant layout and building model are created simultaneously. On brownfield projects, the point cloud generated by the 3D plant scanner is used as a starting point. On greenfield projects, the required information is provided by the customer. With that input, detailed engineering of Aircrete Europe equipment starts, including mechanical and process engineering (piping and ducting, safety fencing). All the data is connected through the Aircrete BIM process, creating a global coordination model, that includes all disciplines and information inherent to the project (Fig. 2).

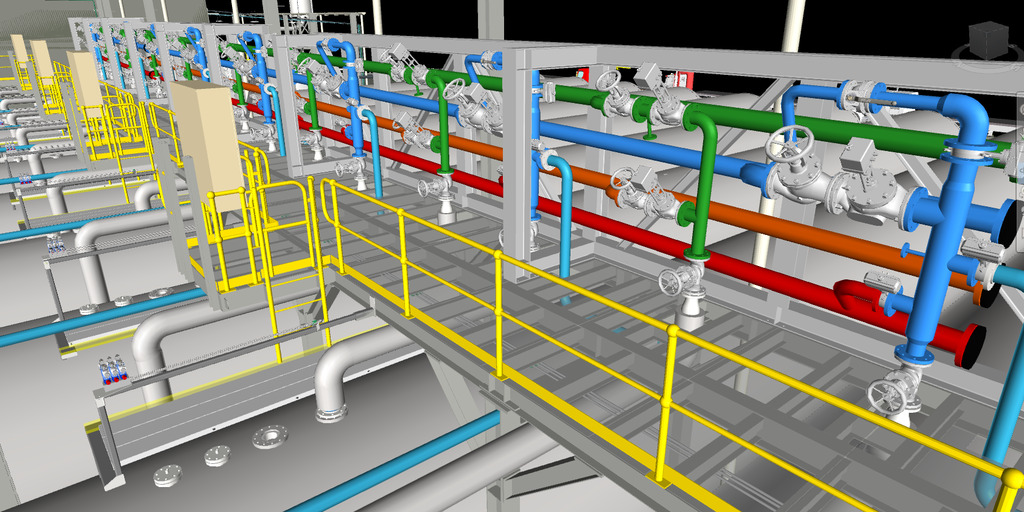

Available to all stakeholders, the global model is used beyond the design phase. As Aircrete projects can have a high level of complexity (particularly brownfield projects), the model is also very useful to execute, for example, a thorough clash analysis. Clash analysis has already been proved to be efficient at Aircrete by being able to identify or solve compatibility issues at an early stage of the project. In addition, BIM modelling allows for pre-fabrication of items like for example of all the piping, hereby reducing the costs and time on site substantially. Taking a step further, another dimension – time – is integrated into the global model, which then, is used for detailed installation planning and manpower planning. Resulting in a visual installation sequence, it facilitates visualization and discussions by simulating the installation process and as a result minimize factory shutdown time (Fig. 3).

Moreover, information on quantities and other reports can be extracted from the Global Coordination Model. That way, Aircrete is able to provide detailed information to the customer for tendering and quoting such services, instead of using estimates.

Finally, after the project is completed, the information is updated to an as-built and “as-performed” version. The result is a digital twin that can be used by the customer for facility management and future upgrade projects.

BIM modelling has therefore become an integrated part of an Aircrete project. Identifying potential issues at an early stage in the project, optimizing installation to minimize factory downtime and providing comprehensive data beyond the project scope are examples of how BIM contributes to a successful project and this underlines Aircrete’s ambition to always aim for the future and find innovative ways to be a true technology partner for its clients (Fig. 4).

The Aircrete Europe YouTube channel is updated with innovative technology on a monthly basis. Check out the advantages of implementing BIM in Aircrete’s projects in this video!

https://www.aac-worldwide.com/channels/aircrete/videos?v=1543

With decades of experience and sales in over 100 different AAC plants in 20 countries on 6 different continents, Aircrete Europe is a recognized global leading developer and manufacturer of Autoclaved Aerated Concrete (AAC) machinery and technology for the production of AAC panels and blocks.

Aircrete Europe designs and delivers highly innovative turn-key AAC plants and cutting-edge plant technology. Being the long-term, exclusive project partner for its customers, Aircrete Europe guides you through all the steps of planning, building and operating your AAC factory. Aircrete Europe is a full technology partner, not just a machine supplier, resulting in maximum value creation for its customers.

This AIRCRETE EUROPE channel and all information presented here is provided by AAC Worldwide - the journal for the Autoclaved Aerated Concrete industry. All articles about AIRCRETE EUROPE are available for free. Feel free to share information from this website with other industry professionals!

Aircrete Europe

Zutphenstraat 6

7575 EJ Oldenzaal

The Netherlands

T: +31 54 157 1020

info@aircrete.com

www.aircrete.com