ARTICLE

Aircrete Europe, 7575 ED Oldenzaal, The Netherlands

Expanding footprint in China with a new panel plant

The demand for AAC panels has further been fueled by the Chinese State Council, who in the last five-year plan set a target of 30% adoption rate for using prefab building solutions in new-built constructions (Fig. 1). To further push efficient and fast building solutions and grow the prefab applications, Premier Li Keqiang released a national strategic plan to develop the manufacturing sector: Made in China 2025. This strategy aims to upgrade the manufacturing capabilities of the Chinese manufacturing industries, thereby converting a labor-intensive industry into a more technology-intensive industry [2]. This also applies to both the construction industry itself, but also to the production technology for building materials.

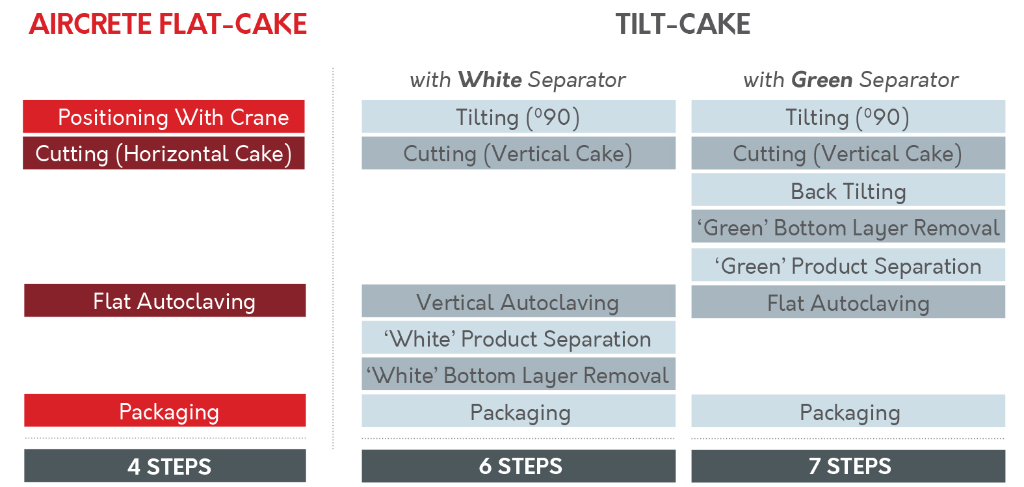

When it comes to AAC, China possesses sufficient factories to cater for the market demand, as China is estimated to provide home over to 2,000 AAC factories nationwide. However, in the surge towards a prefab panel-based building solution, China is facing a major challenge. As the vast majority (>99%) of the Chinese producers still rely on the tilt-cake cutting technology in their AAC factories to produce AAC blocks, there are significant limitations when this technology is used for making AAC panels, particularly for thin panels of 100 mm or thinner (which is the biggest potential market in China) and panels with a super smooth surface (for minimal finishing requirements). This becomes even more challenging when it comes to production of large volumes in a highly automated factory environment, which is one of the key directives of the Made in China 2025 strategy.

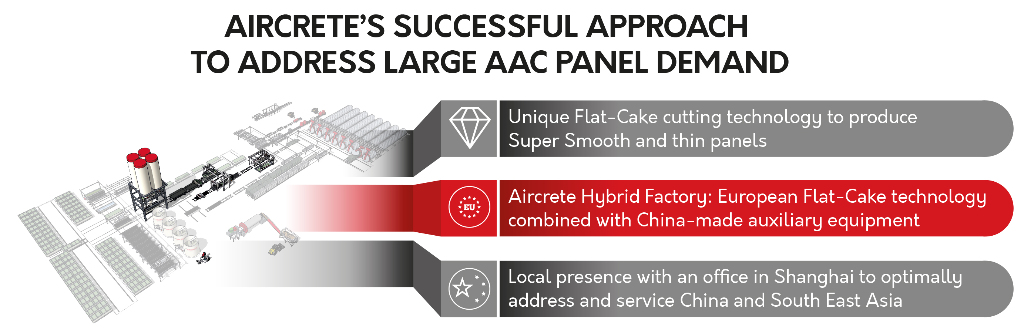

As a leading brand in AAC panel technology, Aircrete Europe is very-well positioned to capitalize on this increasing demand for AAC panel production factories (Fig. 2). First of all, Aircrete factories consist of flat-cake cutting technology, which allows for additional advantages like production of panels with super smooth surfaces or production of panels of 100 mm or thinner. Secondly, with the Aircrete Hybrid Factory, Aircrete is now able to offer a combination of its unique flat-cake cutting technology with non-core equipment coming from China, resulting in a European-based technology factory at attractive pricing for China and South East Asia. Last but not least, with the establishment of a local sales and strategic sourcing office in Shanghai, China, Aircrete is able to optimally address and service their clients in the Chinese and South East Asian markets.

With the commissioning of Aircrete’s latest project in Luoyang, China last year, Aircrete completed yet another project in China, thereby demonstrating that there is a big market for the high-quality technology to produce AAC panels. For its customer, Luoyang Evergreen Building Technology Co. Ltd., a new AAC panel factory based on the Aircrete flat-cake cutting technology has been established to provide an answer to the increasing demand for panel-based prefab AAC solutions in the region.

Like many other projects, this project also started with the Aircrete Phase 1. Over the years, Aircrete Europe has developed a full-scale “Build-to-Suit” AAC plant solution approach, the so-called Phase 1. Combining Aircrete’s experience with a customer focus, Aircrete’s engineers carefully develop a specific plant design which allows for the versatile production of large variety, high-volume and high-quality reinforced panels and traditional blocks in the most efficient manner. Such a customized approach results in transparent investment expectations and an optimal AAC plant infrastructure for the plant`s specific location, eliminating negative design and budget surprises during the project.

This brand new AAC panel and block factory is equipped with 10 autoclaves and has a designed annual capacity of 500,000 m3 in a highly automated mode (Fig. 3 and 4). The plant has the capacity to produce 100% panels, however initial product portfolio is envisaged to consist of predominantly large wall panels, Aircrete Super Smooth partition panels and blocks. As AAC panels will have the largest share of the product portfolio, it was essential for the customer to base the factory on flat-cake cutting technology. In addition, as AAC panel production is relatively new (compared to blocks) in China, it was important for the customer to engage a technology partner that, besides the right technology, also possesses the production know-how of producing AAC panels.

Almost every AAC block plant in China is equipped with a high-speed mixer to mix raw materials and slurry before casting. As AAC panel production is a different ball game, Aircrete Europe has developed a low-speed mixer which is standard for all Aircrete plants. The accurate and reliable Aircrete dosing and mixing system uses an intelligent software control system to measure with high precision. The Aircrete low-speed mixer ensures homogeneous distribution of raw materials in the mix and through its design is especially suited for the panel production, where the cake volumes can vary considerably (Fig. 5).

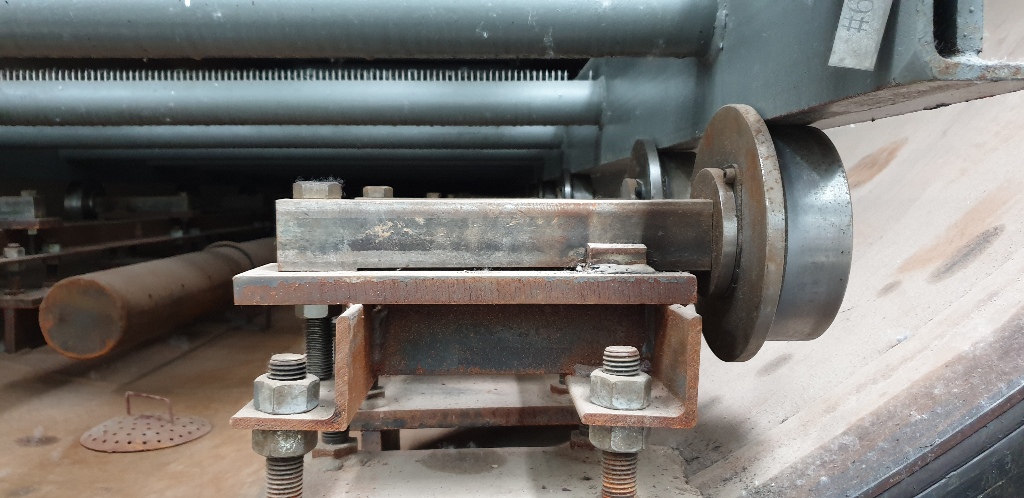

As for every project, an optimized sourcing strategy results in the procurement of certain, less-core items locally (e.g. boiler, slurry tanks, silos, etc.). This approach ensures that the total investment budget is economically optimized without impacting the quality or performance of the plant. Aircrete Europe assists its customers with advising on this optimal sourcing of the equipment. The core equipment (like mixing and cutting technology) always come from the Netherlands, but non-core equipment can be manufactured locally, depending on the availability of local, quality manufacturers. For equipment manufactured locally, Aircrete Europe will ensure that this equipment meets the Aircrete quality requirements and in many cases, the locally produced equipment is produced based on Aircrete specifications and/or drawings. The equipment from the Netherlands is always fully assembled, wired and electrically tested before partly de-assembled and shipped (Fig. 6). This allows, in return, for minimal installation time on site with reduced performance risk during the start up.

As standard part of any Aircrete plant, the factory is based on traditional Aircrete moulds, where all four sides can fold down for cleaning and oiling purposes (Fig. 7) A main advantage of this is the easiness of cleaning and oiling the mould using the automatic Aircrete mould brushing and oiling system. The design of the oiling system with the special low-pressure spray bar with 63 individually adjustable nozzles ensures a huge reduction in oil consumption in comparison with conventional systems (Fig. 8). Aircrete has also developed a new mould oiling system to oil moulds in a closed position, which is for example common practice in China. Depending on the customer’s requirements, either system can be seamlessly integrated in any Aircrete factory.

A further reason why the customer chose for Aircrete is the very limited requirement for special equipment foundations and only the ball mill, mixing tower and cutting line require a special foundation (Fig. 9). Besides the significant positive impact on investment budget, another advantage of very little foundations is that equipment is very easily accessed, and the factory is very easy to keep clean.

The heart of the factory, the cutting line, is of course based on the Aircrete Cutting Line, as the main objective of the customer was to start producing panels. As the Aircrete Cutting Line is designed in order to offer the least possible number of steps of handling a cake during the green stage (i.e. this is the stage before the autoclaving when the cake is still quite vulnerable), it can be considered as optimal technology for making AAC panels. Once the green cake is ready for cutting, the mould automatically opens from all four sides and the grabbing crane picks up the entire green cake, which is positioned on a bed of metal strips and u-profiles (which allow for the maximum flexibility in product portfolio) in the first section of the cutting line.

After a cross-cut is made (determining the length of the panels or heights of the blocks), the cake ‘travels’ on the strips and u-profiles through the High Speed Cutting Frame (HSCF) (Fig. 10). In the HSCF, oscillating steel wires that are pneumatically spanned with two parallel wires per position, make a precise cut that result in very high tolerances (the first cutting wire is followed by a smoothening towing wire) and a very smooth product surface (called Aircrete Super Smooth surface). Due to the super smooth surface, particularly the partition panel product has become popular by builders from all over the world, allowing for significant increase in project efficiencies due to the minimal finishing requirements.

Since the products are cut in a flat position (i.e. the cake is never tilted), the openings between the products are created eliminating sticking problems (that are common problems with tilt-cake systems) and thereby allows for the production of a large product portfolio, including very thin (cladding) panels of 100 mm or thinner. No separating nor green cake tilting machines are used in Aircrete plants reducing the handling of the product and thereby significantly lowering the risks of product damage (Fig. 11).

For this factory in Luoyang, it was chosen to profile AAC products in the green stage (both top and bottom profiling) on the cutting area (Fig. 12). Bottom profiling occurs under the grabbing crane when the product is lifted from the mould. In this plant, Aircrete Europe supplied its new semi-dynamic top profiling with retractable knives in addition to the standard static profiling. This allows to make a combination of panels with profiling and rest-blocks without profiling in one cake. Although profiling in green is a fast and efficient way to profile products that easily meet highest European accuracy standards, Aircrete Europe also offers the possibility to integrated full pack-profiling in the white stage (i.e. after autoclaving) in its factories. Although the investment in this is slightly more expensive than profiling in green, the levels of accuracy and profile quality that can be obtained here are even higher.

After cutting, the curing frames on which the cakes are laying, are stacked with a stacker to three levels high (Fig. 13). With a designated traverser (that can be operated in fully automated mode) the 3-high stacked frames are then pushed into the autoclaves. Autoclaves in Aircrete factories are equipped with rollers with special maintenance-free bearings, reducing the need for autoclave trolleys, also eliminating the requirement of the autoclave trolly circulation (Fig. 14). A major advantage of this system without separate autoclave trolleys in the production process is that it allows for full and easy automation of the full autoclave loading and unloading process.

The project, initiated in 2019, was scheduled to be fully commissioned early 2020. However, due to the global pandemic, international travel restrictions imposed a big challenge for Aircrete professionals to travel to site and supervise the commissioning in the conventional way. Nevertheless, due to a joint effort of the present local installation teams together with Aircrete’s remote commissioning supervision, Aircrete was able to coordinate the full commissioning of this project in June 2020. Readers may refer to the article published on AAC Worldwide, Vol. 3, 2020 for the details of the Aircrete Stay Connected. program [3].

With two Aircrete plants completed in China in 2019 and 2020, a local presence in Shanghai and the Aircrete Hybrid Factory to bring an affordable European panel-based factory to China, Aircrete Europe is set for accelerated growth in the near future, fueled by a significant market demand from AAC panel technology.

The next milestone project is well underway and is expected to be completed in the summer of this year, with anticipated commissioning no later than Q3-2021. In the Keqiao district of Shaoxing city, Aircrete Europe is building a flagship factory for the Chinese and South East Asian market (Fig. 15). This will result in a very modern and automated AAC panel plant, with an expected annual output of 500,000 m3 AAC and with the latest innovations incorporated to make high-quality AAC panels for the Chinese market.

References

[1] “Engine-Only model supplies the “heart” of an AAC panel plant for the South East Asia Markets” AAC Worldwide, Vol. 1, 2019

[2] The State Council The People`s Republic Of China, Made In China 2025 http://english.www.gov.cn/2016special/madeinchina2025/

[3] “Stay connected: remote services products to provide ongoing support” AAC Worldwide, Vol. 3, 2020

With decades of experience and sales in over 100 different AAC plants in 20 countries on 6 different continents, Aircrete Europe is a recognized global leading developer and manufacturer of Autoclaved Aerated Concrete (AAC) machinery and technology for the production of AAC panels and blocks.

Aircrete Europe designs and delivers highly innovative turn-key AAC plants and cutting-edge plant technology. Being the long-term, exclusive project partner for its customers, Aircrete Europe guides you through all the steps of planning, building and operating your AAC factory. Aircrete Europe is a full technology partner, not just a machine supplier, resulting in maximum value creation for its customers.

This AIRCRETE EUROPE channel and all information presented here is provided by AAC Worldwide - the journal for the Autoclaved Aerated Concrete industry. All articles about AIRCRETE EUROPE are available for free. Feel free to share information from this website with other industry professionals!

Aircrete Europe

Zutphenstraat 6

7575 EJ Oldenzaal

The Netherlands

T: +31 54 157 1020

info@aircrete.com

www.aircrete.com