ARTICLE

Aircrete Europe, 7575 ED Oldenzaal, The Netherlands

New automatic unloading line for AAC blocks for Bauroc in Latvia

Fig. 2: Unloading manipulator “during” testing in the Netherlands in 2021.

The market for AAC products is continuously growing. Being one of the largest producers in Northern Europe, Bauroc is increasing capacity while keeping the production reliability at a very high level, which is key for the company to maintain its leading position as a reliable supplier of high-quality AAC products.

Project background

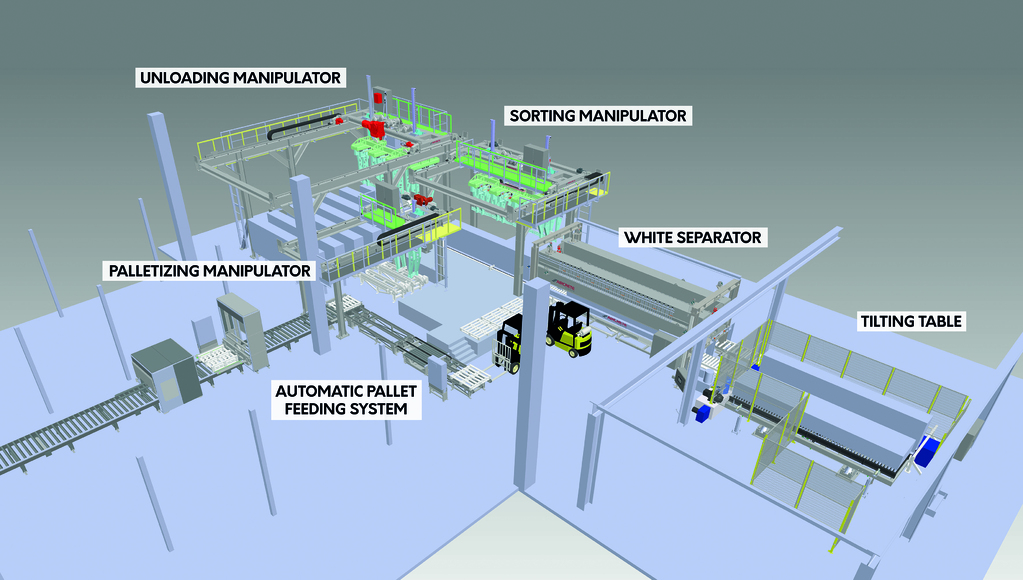

Bauroc has one production site in Ogre, Latvia, which is an existing tilt-and-tilt-back plant with German technology and with flat autoclaving (of three stacks each). The factory has a daily capacity of 700 m3/day of AAC blocks. In order to improve the reliability and safety of the existing forklift-operated palletizing and semi-automated packaging at the Ogre factory, Bauroc initiated an upgrade project of this area to design and install a new, custom-made AAC block unloading and packaging line. In parallel with the new unloading line, Bauroc decided to add one extra autoclave to increase the overall capacity of the factory. Throughout 2020, the technical teams of Bauroc and Aircrete discussed the specific project requirements, based on the desired product quality and line output and within the envisaged investment budget expectations (Fig. 1). The purpose of the investment was to (i) increase the throughput of the unloading line (thus overall plant capacity) and (ii) introduce automated unloading, separation, sorting and re-configuration of the products (within the cake) and palletizing of the autoclaved AAC blocks within the existing factory hall.

Technical description and advantages of the Aircrete solution

As a customized and integrated technology partner, Aircrete took on this project. Although brownfield projects in factories supplied by another equipment supplier are, by definition, more challenging, Aircrete has built up a strong track record of upgrading existing factories based on older technology to ensure they comply with the latest standards and can meet existing and future market demand. The recent largest upgrade of the old tilt-cake factory to a modern Aircrete Flat-Cake technology-based factory for AERCON in the USA is a great example of this. For the full report of this project please refer to the page 52 in the previous edition of AAC Worldwide.

For the Bauroc project in Latvia, similar challenges were faced, the existing parameters (like size of the cake) and layout-related items (like crane positions and the white separator, an element not required in a standard Aircrete design because of no sticking issues) had to be incorporated into the new design, in order to remain within the budget requirements. Nevertheless, Aircrete managed to design a solution that, besides being safer and more reliable, also provides Bauroc with a high level of flexibility regarding unloading and packing variations. The new solution can handle a product portfolio of AAC blocks of 600-625 mm in length, 200-600 mm in height and 50-500 mm thickness. In addition, there is a separate infeed line for special products, such as U-blocks, positioned before the stretch-hood foiling machine. The pallets used in the solution are 1,200 x 800 mm (most popular), 1,200 x 1,000 mm and 1,200 x 1,200 mm, which come stacked and nested in each other to the factory site. Further considerations had to be made for the reinforced AAC panels that Bauroc intends to make in the future, meaning the line needed to be universally suited to cater for both products for a certain part of the unloading. In addition, future plant capacity extension has already been incorporated in the new design.

Finally, because of the sticking issues, resulting from the tilt-cake cutting technology, even with flat/horizontal autoclaving, a separator was required. As Bauroc was concerned about damage to the green cake due to additional handling by a so-called green separator, Aircrete supplied a white separation unit.

All in all, especially due to the restricted space and the flexibility required, the new unloading line from Aircrete had to be compact, multifunctional and efficient (Fig. 2). All of these requirements were met, resembling the strength of the Aircrete organization when it comes to customized, complex engineering, equipment delivery and installation projects.

With the new Aircrete solution, the overall unloading process has an average cycle time of 5 minutes per cake and starts with new tilting table receiving the cake on a curing frame, placed by the existing crane. The cake is then tilted 90 degrees onto the circulating platform, while the curing frame is held back to be removed by the existing crane into the buffer. The cake on the platform then undergoes white separation, layer by layer, and moves forward to the sorting station, where a separate sorting manipulator can remove full layers of blocks and replace them with new ones in case of damage. A fully “clean” cake then goes to the unloading buffer area where a dedicated unloading manipulator can put the full cake on one of the buffer stations for adding extra layers or directly onto the outfeed. A palletizing crane continues to take the whole vertical layer of blocks and, in two moves, places them on the required wooden pallet. Pallet logistics is fully automated from de-nesting, feeding and outfeeding. The existing stretch-hood foiling unit was utilized for foiling the ready products as Bauroc was used to already.

Project preparation and implementation

A solid track-record of designing complex modernization projects which need to be implemented with minimized factory downtime, Aircrete was engaged as the technology partner for this important project, of which the engineering started in the spring of 2021. Clear scope divisions and responsibilities were defined, and a detailed installation preparation plan was worked out by the teams. The installation was realized in the winter factory shutdown of 2021/2022 (Fig. 3 and 4). The known challenges of the pandemic, including price and logistics disruptions, lockdowns, travel restrictions and quarantine requirements did impose an additional challenge on the project, however, despite these challenges, through the excellent cooperation and support from the Bauroc team, the result was achieved within the time frame.

Ivar Sikk, Chairman of the Bauroc Board, commented: “As Aircrete Europe has the right experience and reputation of successfully designing and implementing complex upgrade projects, we engaged them as our technology partner for this important project. This was the first larger project with Aircrete and, even though it was not an easy task to engineer the solution the way we wanted, both teams managed very well. We look forward to a long-term relationship with Aircrete into the future. The fact that Aircrete was able to also arrange attractive project finance, confirmed their status of a true integrated technology partner.”

Attractive Project Finance

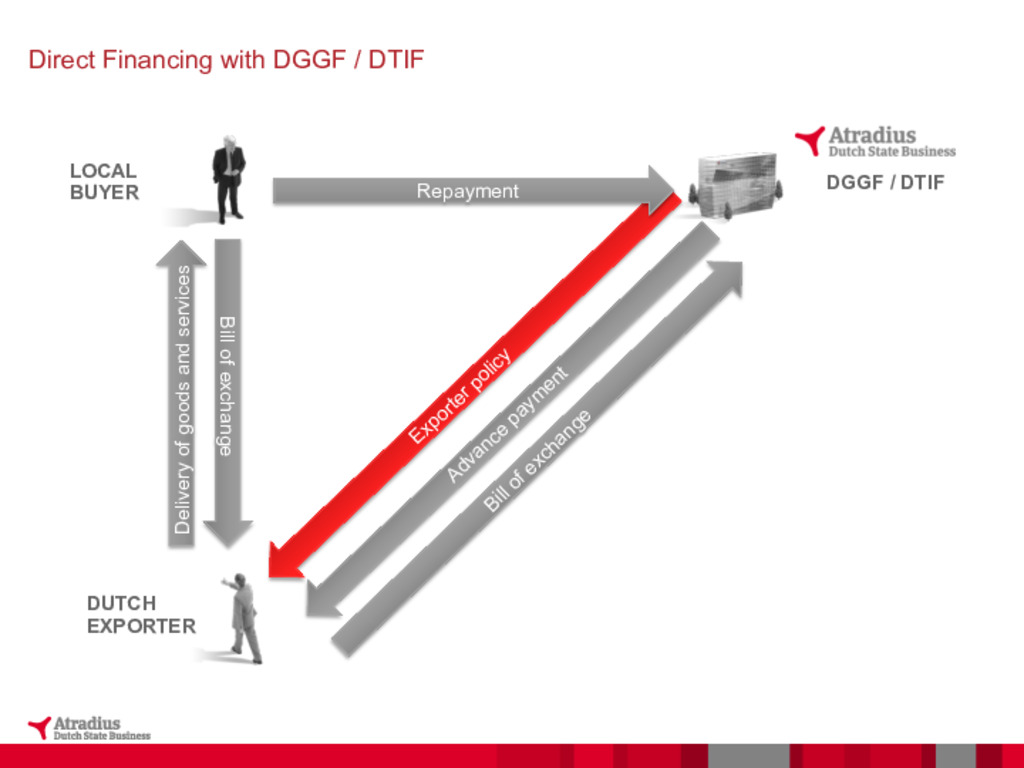

For this project, Aircrete Europe was also able to arrange an attractive project finance for Bauroc. Through different initiatives, the Dutch state offers feasible export finance solutions on the back of the contract with Aircrete. This allows customers of Aircrete to benefit from interesting finance at appealing commercial terms. Aircrete holds very good relationships with the stakeholders involved in these processes (like Invest International (formerly known as FMO) and Atradius), which have also already been involved in several projects from Aircrete in the past (e.g. Argentina in 2016 and Uzbekistan in 2021). The finance solutions can be arranged through a buyer’s credit or a seller’s credit. Under a buyer’s credit, the loan can be structured either directly with the client, or a bank-to-bank loan with a client’s (local) bank. Due to the “green” and sustainable nature of AAC plants, these types of projects have received an increased level of attention from Dutch state funding providers as AAC factories produce a green building material and are thereby contributing to the sustainable building culture of the future.

For Bauroc project in Latvia, Atradius was involved as the financing partner. The project finance was structured as a seller’s credit, which means that in principle Aircrete is providing 85 % of the financing to Bauroc at an attractive interest rate and with a long-term finance structure (Fig. 5). Through Bill of Exchanges (BoE), Bauroc and Aircrete agreed on the future interest payments and loan repayments, which would only start taking place for the first time six months after completion of the project. After the successful commissioning, all BoE were acquired from Aircrete by Atradius and Aircrete received the future payments linked to the BoE. Atradius in return will collect the payments from Bauroc directly in the future. This structure allowed Bauroc to execute this project while maintaining a high level of liquidity (otherwise used for the project) which is beneficial to support Bauroc’s abundant growth opportunities in the near future.

Marijn Kastelein, Senior Export Credit Specialist at Atradius Dutch State Business, commented: “I am very happy to see yet another transaction in which Aircrete Europe is a stakeholder. In our role to provide Dutch export companies with export finance products for their projects, ESG assessment has become a fundamental part of our application process. The exporting company, the product or equipment being exported, and the client’s business activity all need to meet our ESG requirements in order for us to facilitate the project with export funding. With Aircrete Europe we have already successfully realized multiple projects and their organization in combination with the green building materials that their equipment is able to produce, makes it a perfect example of successful export funding in practice!”

About Bauroc

Bauroc (until early 2017 AEROC) is the largest producer of AAC products in Northern Europe. The family-owned group was established in 2001 and has yearly turnover of about 65 million Euros and employs 240 people in four countries. Bauroc operates three modern AAC factories in Baltics and calcium silicate factory in Lithuania. The company sells its products in all Baltic and Nordic countries but also in Iceland, Poland, Germany and Switzerland under the “bauroc” and “roclite” brand names. Calcium silicate is sold under “silroc” brand. Under these brands, Bauroc offers a large and diversified product portfolio, including a wide range of block products, reinforced lintels, large roof and wall elements, instruments, dry mixes and accessories for installing the products. In addition, under the JAMERA brand, Bauroc offers a full building solution with the delivery and assembly of house packages. Based on AAC products, JAMERA is functional, and energy efficient house concept built for the Nordic climate and providing exceptionally healthy indoor environment.

With decades of experience and sales in over 100 different AAC plants in 20 countries on 6 different continents, Aircrete Europe is a recognized global leading developer and manufacturer of Autoclaved Aerated Concrete (AAC) machinery and technology for the production of AAC panels and blocks.

Aircrete Europe designs and delivers highly innovative turn-key AAC plants and cutting-edge plant technology. Being the long-term, exclusive project partner for its customers, Aircrete Europe guides you through all the steps of planning, building and operating your AAC factory. Aircrete Europe is a full technology partner, not just a machine supplier, resulting in maximum value creation for its customers.

This AIRCRETE EUROPE channel and all information presented here is provided by AAC Worldwide - the journal for the Autoclaved Aerated Concrete industry. All articles about AIRCRETE EUROPE are available for free. Feel free to share information from this website with other industry professionals!

Aircrete Europe

Zutphenstraat 6

7575 EJ Oldenzaal

The Netherlands

T: +31 54 157 1020

info@aircrete.com

www.aircrete.com