ARTICLE

Aircrete Europe, 7575 EJ Oldenzaal, The Netherlands

New Generation Slurry Density Measurement Device

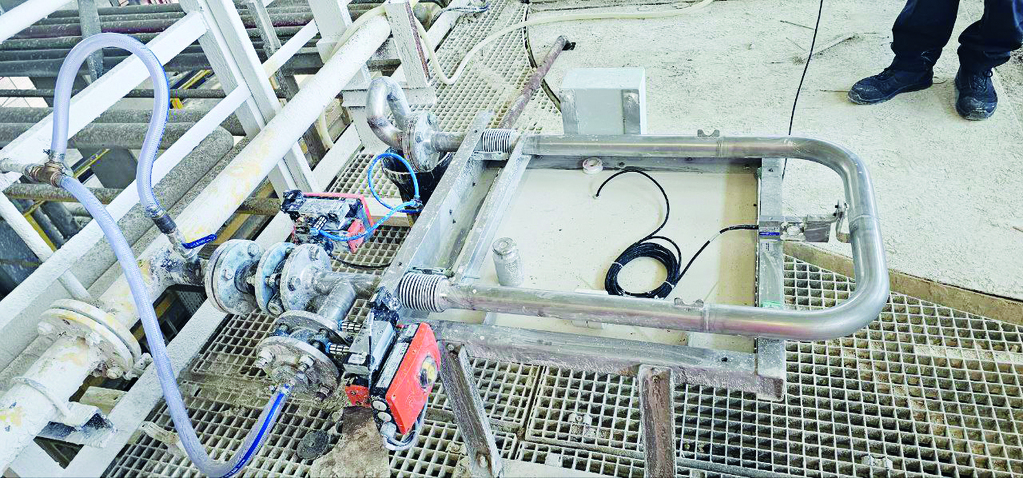

Fig. 1: New generation slurry density measurement device in an existing plant in Türkiye.

New developments

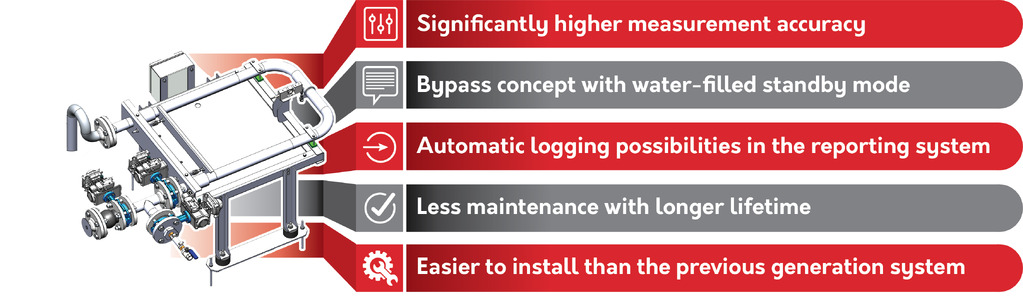

The new generation Aircrete DMD introduces significant advancements in measurement accuracy. With its innovative design, the system achieves an impressive accuracy of up to 9 kg/m³, a substantial improvement over earlier models. This level of precision ensures tighter control over AAC production, directly contributing to the consistency and quality of end products.

A key feature of the redesigned DMD system is its water-filled standby mode. Unlike traditional setups where slurry continuously flows through the pipe, the new bypass design only allows slurry to enter the pipe of the DMD during specific intervals for measurement. Between cycles, the pipe of the DMD remains filled with water that serves as a density reference point, enabling automatic recalibration before each cycle. Furthermore, should something go out of order within the system, water density reading will show a significant difference from the actual water density, adhering to more optimized on-demand maintenance.

Advantages of the new system

The new Aircrete DMD offers several advantages that set it apart from traditional systems. Foremost among these is its high accuracy, ensuring precise density measurements for maintaining consistent product quality in AAC production. Additionally, filling the system with water on the standby mode prevents material build-up inside the pipe, significantly reducing wear and extending the device's lifespan. A common issue in systems with continuous slurry circulation is the pump vibrations affect on the load cell – the bypass concept of the new Aircrete DMD eliminates this influence.

The new Aircrete DMD not only enhances measurement reliability and accuracy, but also simplifies integration into existing plant infrastructures, making it easier to adopt without extensive modifications. These features collectively make the DMD a robust and user-friendly solution for modern AAC manufacturing needs.

Conclusion

In conclusion, Aircrete's new Density Measurement Device marks a significant advancement in AAC production technology. Its high accuracy, water-filled standby mode for automatic recalibration, and resistance to material build-up offer substantial improvements in reliability and longevity. By addressing issues like pump vibration interference, and simplifying installation within existing plant infrastructure, this new generation system provides a practical and efficient solution for modern AAC manufacturers. With its innovative design and robust performance, the new DMD is set to enhance quality control for any AAC manufacturer out there.

With decades of experience and sales in over 100 different AAC plants in 20 countries on 6 different continents, Aircrete Europe is a recognized global leading developer and manufacturer of Autoclaved Aerated Concrete (AAC) machinery and technology for the production of AAC panels and blocks.

Aircrete Europe designs and delivers highly innovative turn-key AAC plants and cutting-edge plant technology. Being the long-term, exclusive project partner for its customers, Aircrete Europe guides you through all the steps of planning, building and operating your AAC factory. Aircrete Europe is a full technology partner, not just a machine supplier, resulting in maximum value creation for its customers.

This AIRCRETE EUROPE channel and all information presented here is provided by AAC Worldwide - the journal for the Autoclaved Aerated Concrete industry. All articles about AIRCRETE EUROPE are available for free. Feel free to share information from this website with other industry professionals!

Aircrete Europe

Zutphenstraat 6

7575 EJ Oldenzaal

The Netherlands

T: +31 54 157 1020

info@aircrete.com

www.aircrete.com