ARTICLE

Aircrete Europe, 7575 EJ Oldenzaal, The Netherlands

State-of-the-art solutions for aging Hebel plants – Part 1

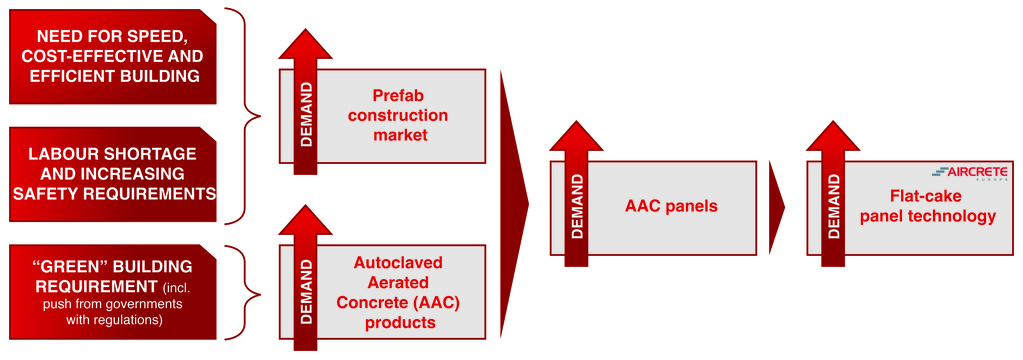

Fig. 2: Trends towards greener construction, speed in construction projects and labour shortage are the main drivers for an increasing demand for flat-cake AAC technology.

This article examines how Aircrete Europe’s advanced Flat-Cake technology presents an optimal solution for upgrading Hebel-based factories, particularly focusing on the cutting line - a critical component in AAC production. As the only provider of AAC Flat-Cake technology in the industry, Aircrete Europe is very well positioned to execute such complect modernization projects. The article should moreover be read in a broader light as, besides Hebel upgrades, it is also applicable to other flat-cake and/or tilt-cake technologies.

The evolution of Hebel technology and the rise of prefab modular construction

Hebel technology has been a foundational element in AAC production since the mid 1940’s. Its Flat-Cake method, which allows for the production of both panels and blocks, has long been valued for its ability to create durable, high-quality building materials. However, the landscape of AAC production has undergone significant changes due to industry consolidation, shifting market demands and rapidly improving technological advancements.

In the late 20th century, three of the original four major AAC producers – Hebel, Durox, and Ytong – were consolidated into Haniel Bau, later known as Xella Group. Xella, focusing primarily on producing AAC products for the European Union market, discontinued its international licensing and project engineering activities, leading to a decline in the global promotion and development of Hebel’s Flat-Cake technology. For more details, please refer to the article “History of Autoclaved Aerated Concrete” in the 1st edition of AAC Worldwide in 2018.

Recognizing the potential of this technology in the beginning of this century, Aircrete Europe revived and further developed the Durox Flat-Cake technology under the Aircrete brand, today a well-known brand in the global market for AAC panel (and block) technology. By reintroducing this technology under the Aircrete brand, the company not only preserved the legacy of Hebel’s Flat-Cake method but also brought it into the modern era. Over the years, Aircrete Europe has evolved into a global vertically integrated company with decades of expertise in developing Flat-Cake AAC production technology, making significant technological advancements that have set new standards in the industry (Fig. 1).

One of the most significant trends in the construction industry today is the growing demand for prefab modular (AAC) construction, driven by the need for speed, cost-savings and efficiency in construction projects and an ever-increasing shortage of skilled labor and on-site safety requirements, further complemented by the surge for greener construction projects (Fig. 2). This method, which involves manufacturing building components in a factory setting before assembling them on-site, requires materials that are precise, versatile, and capable of meeting stringent quality standards. Flat-Cake technology, with its ability to produce thin, high-quality panels with a smooth surface (all in high-volume production and with minimal waste levels), is particularly well-suited to meet these demands.

Aircrete as the right technology partner for Hebel-based factories

Some factories that have long relied on Hebel Flat-Cake technology are now facing a critical juncture. Many of these plants are aging, and the manual processes that once defined efficiency and an increasing awareness for the safety of operators, are increasingly becoming limitations. While Hebel technology has been a reliable workhorse, the need for modernization is becoming more apparent as the industry shifts towards more automated and precise production methods.

Hebel systems, being part of the “flat-cake family” are particularly known for their ability to produce thinner AAC products (100mm or thinner), a feature that remains in demand as the construction industry continues to prioritize lightweight, versatile building materials. However, the manual handling and cutting processes characteristic of Hebel systems can lead to variability and inefficiencies that are less compatible with the precision that will be required in future prefab modular construction projects.

Aircrete Europe’s Flat-Cake technology addresses these challenges, particularly in the mould circulation and cutting line areas, by introducing advanced automation and precision into the production process. With respect to the mould circulation, a major advantage, besides the additional flexibility, is the ability to cover fully the rising area, thereby ensuring maximum consistency for the production process (Fig. 3). Aircrete panel factories are standard equipped with fully-automated adjustable mould doors for flexible and efficient panel production with zero waste. This is also a special solution to upgrade the traditional damming walls or manually movable back doors in traditional Hebel factories. The Aircrete Movable Mould Door is a typical invention for a real AAC panel factory, to avoid the casting of by-products when the focus is on panel production instead. This system is designed specifically for real AAC panel factories that require the capability to produce short cakes (e.g., 4.5 meters long) in a 6-meter-long mould. The Movable Mould Door, integrated into the stationary mould, is automatically adjusted to a pre-set position between 3 and 6 meters by an Aircrete Movable Door Manipulator. This design eliminates the need for separate storage, cleaning, and oiling, as the door remains part of the mould system. The result is optimized cycle times, minimized green waste, and a simplified unloading and packing process. The Movable Mould Door system enables factories to expand their product portfolio with greater flexibility while maintaining high production efficiency and quality (Fig. 4). For more details, please refer to the article “Adjustable moulds for flexible and efficient panel production with zero waste” in the 4th edition of AAC Worldwide in 2019.

With respect to the cutting line, the heart of an AAC plant, in summary the advantages of the Aircrete technology when upgrading a Flat-Cake technology result in less operators required, improved operator safety, superior product quality and higher capacity output (Fig 5). All these advantages are described in more detail in the next section.

Cutting line as the heart of an AAC plant

When it comes to the cutting line, there are a number of distinctive improvements Aircrete brought to the market when upgrading a traditional Hebel cutting line. In this part 1 of this article, the focus is more on the replacement of the mould circulation and cutting line.

In the Aircrete system, once the cake is finished rising and is ready for cutting, the mould automatically opens from all four sides and the grabbing crane picks up the entire green cake and brings it to the cutting line, where it is lowered onto the cross cutter. The use of moulds that can open fully on all sides has the advantage of very effective cleaning and oiling. Aircrete offers a mould transport solution that is based on roller tables, which allow you to implement a new mould circulation without the requirement of doing extensive civil works, saving money, but especially reducing down-time tremendously (Fig 6.)

In the traditional Hebel cutting line, once the cake is finished rising and is ready for cutting, the mould crane picks up the sides of the moulds with the crane that hold the green cake and brings the cake to the cutting line table. This process is not automated and performed by an operator in most of the plants. Furthermore, in the Aircrete system the grabbing cake picks up the cake directly, rather than the sides of the moulds, making the Aircrete system more reliable. However, the Aircrete can also adapt its cutting line design in such a way that it can continue to use the existing Hebel moulds and cranes and also has update packages for these, which will be presented in part 2 of this article.

Aircrete offers a wide range of upgrade packages for existing Hebel cutting lines, which will also be described in more detail in part 2 of this article. However, on several occasions, clients have opted to completely replace the existing Hebel cutting line with an Aircrete Flat-Cake cutting machine. As Aircrete is generally able to adjust the design of the new cutting machine to fit into the existing foundation, this has a big advantage for the clients, as the down time of the plant is therefore minimized. In addition, most of the existing frame logistics can be fully reused.

In the high capacity plants the cross cut is made first in a separate cross cut position, ensuring very short cycle times (Fig. 7). The separate cross cut position has extra short wires for and even higher accuracy of the cross cut of the cake. Also, the separate cross cut position allows for compacting of the cake without high external forces, resulting in lower production risk.

Also for the vertical cut, the Hebel system uses static wires that are pulled through the cake, resulting in lower accuracy, and in addition, there is no option to create super smooth surfaces. Furthermore, because of the needles, the vertical cut (i.e., block thickness) is not flexible in the Hebel system. In the Aircrete system, after the cross cut, the ‘pusher’ advances and gently rolls the cake on its frame steel bars (or strip bed) towards the High-Speed Cutting Frame (HSCF) (Fig. 8). In the HSCF, the wires are oscillating, resulting in higher accuracy of the product. In addition, the Aircrete cutting system uses a double wire system for the vertical cut, resulting in products with a super smooth surface for a premium appeal and cost saving advantages on construction projects. One additional advantage is increased flexibility, as with the Aircrete HSCF, the vertical cut allows for intervals of 5mm, creating a much larger product portfolio of possible block thicknesses.

In the Aircrete system, the front and end crust of the cake are automatically removed by an end-needle plate and the vacuum crane removes the top crust automatically. This automation not only increases safety by reducing the need for operators to work near potentially dangerous machinery but also ensures a more consistent removal process, which is crucial for maintaining high product quality. The removal of the crusts in the Hebel system is semi-automated. The top crust is automatically removed by a top crust screw and the front and end-crust are manually removed by the cutting line operators. In both systems, all crusts are 100% recycled back into the production process.

Solid track record

Aircrete Europe’s expertise in modernizing Hebel-based factories is well-documented, with successful case studies ranging from smaller and very large upgrades of Hebel factories around the world. In one of Aircrete most recent Hebel upgrade projects, Holcim Romania, the installation of the latest Flat-Cake technology enhanced capacity, product quality, and production efficiency, making the plant one of the most advanced AAC facilities in the region. For more details, please refer to the article “Holcim’s AAC plant in Romania upgraded with latest flat-cake technology to enhance capacity, product quality and production efficiency” in the 1st edition of AAC Worldwide in 2024.

Similarly, the comprehensive upgrades carried out at SYC’s facility in South Korea, besides the cutting line automation and capacity upgrades were implemented in the unloading and packing area, demonstrate Aircrete’s ability to implement complex, holistic improvements that significantly boost production capabilities while maintaining the integrity of the existing infrastructure (Fig. 10). For more details, please refer to the article “Complex upgrades made easy: A holistic approach for enhanced capacity” in the 2nd edition of AAC Worldwide in 2020.

For Hebel-based factories, partnering with Aircrete Europe to upgrade to Flat-Cake technology offers a clear and compelling path to modernization. The combination of enhanced automation, improved cutting precision, and streamlined material handling can significantly boost production efficiency and product quality. This is particularly important as the demand for prefab modular construction continues to rise, requiring manufacturers to meet ever-higher standards of precision and speed.

Conclusion and final considerations

While the cutting line remains the heart of any AAC production facility, modernizing other aspects of the factory is equally crucial for enhancing overall efficiency and product quality. Aircrete Europe’s innovations extend well beyond the cutting line, providing comprehensive solutions that address key areas of the production process. These include innovations that are not specifically targeted at Hebel factories, but are applicable to any other flat-cake and even many tilt-cake factories. During the past two decades, Aircrete has continuously brought new innovations to the market to provide factory owners with safer and better solutions to improve their operational efficiency, increase operator safety and improve product quality.

Before undertaking any upgrade, whether large or small, it is essential for factory managers to conduct a comprehensive assessment. This assessment helps identify the areas where improvements will have the most significant impact, ensuring that the upgrades are tailored to the specific needs of the factory. A strategic approach to modernization maximizes return on investment by focusing on the most critical aspects of the production process. Aircrete’s Phase 1 product has proven many times to be a logic and sensible first step in a history of many successful upgrade projects.

Part 2 of this article will follow in the next edition of AAC Worldwide and will provide information of smaller upgrade packages to several parts of a Hebel plant.

With decades of experience and sales in over 100 different AAC plants in 20 countries on 6 different continents, Aircrete Europe is a recognized global leading developer and manufacturer of Autoclaved Aerated Concrete (AAC) machinery and technology for the production of AAC panels and blocks.

Aircrete Europe designs and delivers highly innovative turn-key AAC plants and cutting-edge plant technology. Being the long-term, exclusive project partner for its customers, Aircrete Europe guides you through all the steps of planning, building and operating your AAC factory. Aircrete Europe is a full technology partner, not just a machine supplier, resulting in maximum value creation for its customers.

This AIRCRETE EUROPE channel and all information presented here is provided by AAC Worldwide - the journal for the Autoclaved Aerated Concrete industry. All articles about AIRCRETE EUROPE are available for free. Feel free to share information from this website with other industry professionals!

Aircrete Europe

Zutphenstraat 6

7575 EJ Oldenzaal

The Netherlands

T: +31 54 157 1020

info@aircrete.com

www.aircrete.com