ARTICLE

Aircrete Europe, 7575 ED Oldenzaal, The Netherlands

Tarmac UK in control of AAC production process with innovative solutions and increased operator safety

Many AAC producers worldwide use a vacuum hood to remove top and end crusts of the green cake after cutting. Although removal of the crusts by vacuum is an efficient and clean solution, removing the end crusts can turn out to be more challenging in practice than the top crust.

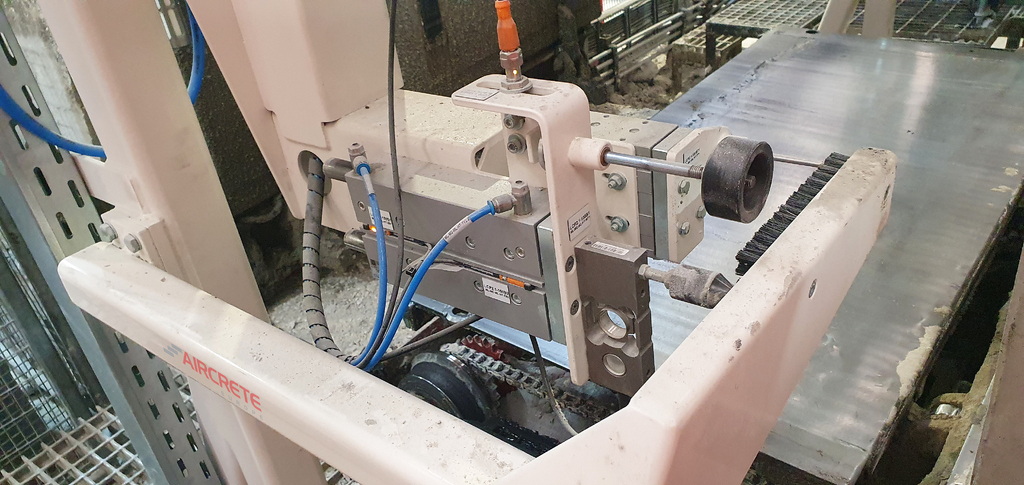

As the surface of the front and back crust might not be uniform enough (e.g. due to corner damages to the waste crust), the automatic removal by vacuum might not work optimally. Not only does this interrupt the production, it also requires operators to enter into the safety zone to remove the remaining crust by hand. As a result, Aircrete Europe developed an upgrade for the vacuum crane, whereby the vacuum end-hoods are replaced with needle-plate end-hoods. A needle plate is a movable plate with needles (that move through another plate with holes) to penetrate the front and end crust of the green cake. Without any suction force, the needles hold the crust of the green cake and move it to the crust pit area. By moving the needle-plate backwards, the second plate holds the crust and the needles retract from the crust and the crust is dropped in the crust pit. This solution has turned out to be more reliable as a fully uniform surface is not required anymore and, in addition is more energy efficient, easier in maintenance, and, due to the use of the same fasteners and cylinders from the former hood design, easier to install (resulting in very limited downtime when installed in existing factories). Both the software and hardware of the control system can be implemented into the existing control system with minimum changes as well (Fig. 1).

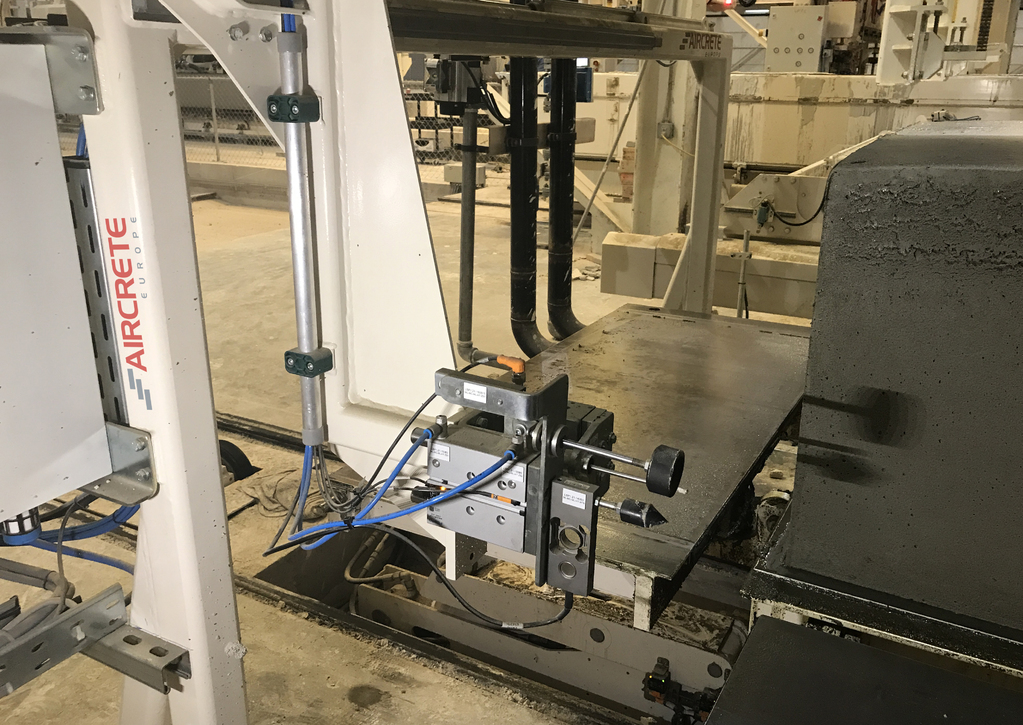

The second upgrade, the automatic green cake Hardness and Temperature Measurement Device, addresses a different challenge in the AAC production process. From the early days of AAC production, the correct hardness of the green cake has been a vital element for successful AAC production. Today in many factories this is still done by hand through a traditional thermometer and penetrometer. The latter is a simple hand tool that is used to measure the hardness of the green cake before cutting, whereby an operator manually measures the hardness by sticking the penetrometer in the green cake after opening of the mould. The result of this manual measurement provides the operator with information about the cake and subsequent actions can be put in motion. For example, an adjustment of the cutting line speed (e.g. a slower cutting speed if the cake is too hard) or whether the grabbing crane is able to grab the cake (e.g. when the cake is still too soft). A major disadvantage of this way of measuring is, besides being very labor intensive, an operator needs to enter the safety zone of the equipment, thereby disrupting the process and/or creating an un-safe situation for the operator.

As one of the latest innovations with respect to plant safety improvements, Aircrete Europe developed an innovative and automated solution that was implemented in Tarmac factory in Linford in the UK. The automatic green cake Hardness and Temperature Measurement Device is easily integrated into the cutting line. The unit, fixed on its own small gantry, can move to the end-crust of the cake to take the hardness and temperature measurements from the green cake before cake pick up through a cone and a probe. Besides a more reliable and precise way of measuring the cake’s hardness and temperature, the results are also automatically registered in the plant control database and can be applied for additional applications, including possible changes to the recipe for production optimization (Fig. 2).

Matt Jenkinson, Senior Operations Manager Blocks at Tarmac, commented: “Through these new upgrades, that were implemented by Aircrete without any significant production stop, we have improved the safety situation in our factories. In addition, through automated and consistent measurement we are benefitting now from being better in control of our AAC production process. “

On a continuous basis, new innovations are being introduced to the market by Aircrete to support plant owners with the challenges they are facing. Whether it is to improve the safety situation of operators, to enhance the quality of the end product, to automate the technology or to simply allow plant operators to be in full control of their production process, Aircrete has developed the solution for it and, if it doesn’t exist yet, Aircrete will develop it! (Fig. 3).

With decades of experience and sales in over 100 different AAC plants in 20 countries on 6 different continents, Aircrete Europe is a recognized global leading developer and manufacturer of Autoclaved Aerated Concrete (AAC) machinery and technology for the production of AAC panels and blocks.

Aircrete Europe designs and delivers highly innovative turn-key AAC plants and cutting-edge plant technology. Being the long-term, exclusive project partner for its customers, Aircrete Europe guides you through all the steps of planning, building and operating your AAC factory. Aircrete Europe is a full technology partner, not just a machine supplier, resulting in maximum value creation for its customers.

This AIRCRETE EUROPE channel and all information presented here is provided by AAC Worldwide - the journal for the Autoclaved Aerated Concrete industry. All articles about AIRCRETE EUROPE are available for free. Feel free to share information from this website with other industry professionals!

Aircrete Europe

Zutphenstraat 6

7575 EJ Oldenzaal

The Netherlands

T: +31 54 157 1020

info@aircrete.com

www.aircrete.com