ARTICLE

Keda Suremaker, Maanshan City, Anhui Province, China

Driving efficiency in AAC production: the strategic role of auxiliary equipment

It is precisely in these seemingly ”minor” processes that auxiliary equipment proves its value. They may not be the stars of the production line, but they make operations more stable, environmentally friendly, and efficient. Keda leverages this innovative auxiliary machinery to turn operational details into real competitive advantages for its customers.

High-frequency slurry vibration: unlocking uniform foaming

Uniform foaming of the green cake directly determines compressive strength, cutting accuracy, and final yield. Traditional reliance on experience and manual adjustments often results in large air pores and uneven foam, wasting aluminium powder and compromising quality.

Keda´s high-frequency vibration system operates at approximately 200 Hz and 12,000 rpm, using resonance to break down large air pores into evenly distributed micro-pores instead of simply expelling air. This optimizes foaming conditions and ensures uniform pore distribution and density.

Its modular design allows easy integration into new or retrofitted lines, while advanced cooling extends the lifespan of the controller and ensures long-term stability. As a result, customers reduce aluminium powder usage and overall production costs, and achieve more consistent green cake quality and higher cutting accuracy.

Customer benefits of improved slurry vibration

Customer benefits include:

· Improved product consistency and stability

· Reduced aluminium powder consumption

· Enhanced cutting efficiency and yield

Mould oiling machine: efficiency meets sustainability

Demoulding is a critical step in AAC production, where even minor errors can damage or waste green cakes. Manual oiling is inefficient and inconsistent, which frequently leads to demoulding failures.

Keda´s mould oiling machine employs servo-driven motion and closed-loop control for automatic travel, precise positioning, and spraying. With a cycle time of only 80 seconds per 6 m mould, rotating spray heads ensure full coverage with adjustable thickness for different green cake specifications.

The enclosed spraying process prevents splashing and meets environmental standards. Dual oil tanks allow simultaneous refilling and production without affecting cycle time. This equipment improves demoulding success rates, efficiency, and green production.

Customer benefits of the improved mould oiling machine

Customer benefits include:

· Higher demoulding success rate

· Reduced labour dependency

· Continuous production with environmental compliance

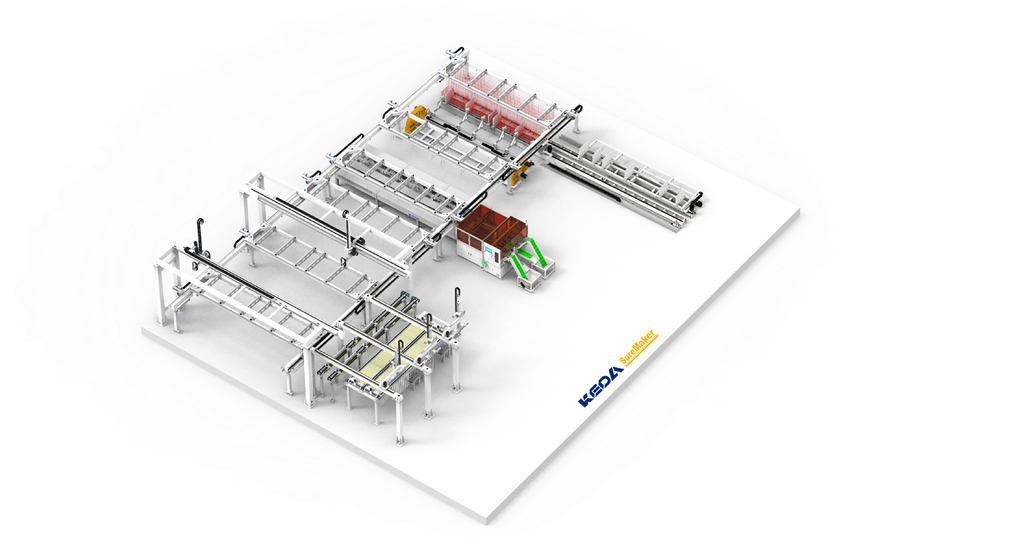

Automatic reinforcement steel mesh cage assembly: enabling AAC panel production

In AAC panel production, reinforcement cages determine panel strength and durability. Manual assembly is slow and imprecise, unsuitable for high-capacity and high-cycle production lines.

Keda´s automatic steel mesh cage assembly system consists of three core modules:

1. Saddle frame adjustment & steel needle exchange: Precise frame transfer with efficient steel needle regrouping.

2. Fixing clip sorting & installation: Vision-guided system with six collaborative robots for intelligent sorting and precise installation of plastic clips.

3. Mesh steel cage placement: Six robotic manipulators simultaneously handle single or multiple steel cages, completing assembly quickly while maintaining continuous operation.

Focusing on minimal labour input and streamlined workflow, the system ensures assembly precision and provides a stable production rhythm, significantly enhancing capacity and consistency. Customers can achieve scalable, high-value panel production, meeting market demands for strong and durable products.

Customer benefits of automatic reinforcement cage assembly

Customer benefits include:

· High automation with minimal labour

· Stable rhythm and assembly accuracy

· Scalable, high-value panel production

As the AAC industry continues toward digitalization and sustainability, auxiliary automation systems are emerging as key drivers of production competitiveness. Slurry vibration, mould oiling and automatic cage assembly may not be considered core production equipment, but play decisive roles in ensuring quality, boosting efficiency, and supporting sustainable production.

Keda believes that true competitiveness is born in the details of process engineering. With innovation as its driving force, Keda will continue empowering customers with smarter, greener, and more efficient AAC plants, contributing to the high-quality development of the industry.

KEDA SUREMAKER (Anhui KEDA Industrial Co., Ltd) is a holistic autoclaved aerated concrete plant solution supplier from China, providing customers with customized service including production process and formula design, equipment R&D, manufacturing, plant engineering, personnel training, and operation management consulting, etc. In both Chinese market and the overseas AAC market, KEDA has demonstrated its strong momentum. Nowadays, the AAC plants powered by KEDA SUREMAKER have been distributed to Europe, Southeast Asia, the Middle East, South Asia, South America.

As the vice president unit of China Aerated Concrete Association and the associated member of European AAC Association, KEDA SUREMAKER is in charge of editing the China AAC industry standards and is committed to promoting the development of the worldwide AAC industry.

KEDA SUREMAKER Holistic AAC Plant Solution, make sure of your success.

Anhui KEDA Industrial Co., Ltd

2887, Tianmen Rd, Economic & Technological Development Zone, Ma’anshan, Anhui Province

China

www.kedasuremaker.com

info@keda-suremaker.com