ARTICLE

Keda Suremaker, Ma’anshan, Anhui Prov., China

State-of-the-art AAC plant in China integrates innovations in technology, efficiency, and intelligent solutions

As early as 2010, Keda Suremaker provided a holistic AAC Plant Solution for the BBMG AAC production base in Beijing. Following the project's completion, the equipment operated efficiently and stably for an extended period, with timely and responsive services, garnering positive feedback from customers. To align with the development trend of the construction market in Northwest China, BBMG once again partnered with Keda Suremaker to expand its presence in the region and establish a demonstration project. The project has been successfully operational for one year, rewarding the trust placed by this longstanding Chinese AAC production enterprise in Keda Suremaker's technological prowess and service capabilities.

As a holistic AAC plant solution supplier, Keda Suremaker has established several research and innovation platforms including a national postdoctoral research station and the Anhui Province Engineering Technology Research Center. Keda Suremaker can offer comprehensive solutions and services for entire production lines, including project proposals, raw material analysis, process and formulation design, plant planning, equipment development and manufacturing, project management (EPC/EP), personnel training, operation management, and product application consultation. In this collaboration with BBMG Shanxi AAC Plant, Keda aims to leverage technical expertise to facilitate intelligent and efficient production in this flagship demonstration project.

In the comprehensive project solution for this project, Keda Suremaker has integrated its latest technological research achievements and highlighted an efficient production solution. Significant progress has been made in intelligent production, resulting in a 42% reduction in labor utilization. Utilizing our independently developed intelligent production scheduling system, we have provided strong support for intelligent manufacturing and automated production. Large-screen dashboards were installed at key production positions, including material tank displays, pouring records displays, equipment management displays, and autoclave displays, in addition to the main scheduling center screen. This intelligent production scheduling system has greatly improved the efficiency and management level of production planning and scheduling. It not only supports business rollbacks but also allows for manual adjustments, achieving flexible and intelligent production scheduling.

To reduce carbon emissions, the project has implemented an autoclave automatic control system to fully utilize steam and waste heat, as well as utilizing photovoltaic power generation. The entire production line is designed with zero wastewater discharge energy-saving processes. To assist customers in producing boards more quickly and efficiently, intelligent steel reinforcement cage meshing technology was introduced into the production line, aiming to help customers save labor costs and improve production efficiency.

Crane and ferry car are important conveying equipment for the AAC block and panel production line. The stability and efficiency of equipment are important constraints on product quality and capacity. Keda Suremaker completed the following research and development projects based on the actual application of the AAC projects.

Hoisting mode of crane: The lifting process of the crane adopts hydraulic lifting and gear rack forced mechanical synchronization, which is stable and reliable, with high synchronization and superior safety. The hydraulic lifting mode is especially suitable for AAC panel production.

Walking and positioning mode: The positioning accuracy of crane and ferry car is very important. Inaccurate positioning can easily cause operation failure of the production line. Therefore, both crane and ferry car need appropriate walking and positioning forms. The crane of Keda Suremaker is driven by servo motor & reducer, the walking is guided by gear rack and combined with a dynamic precision detection encoder to ensure accurate walking positioning, as well as stable and reliable operation. The ferry car adopts a double reducer drive combined with a mechanical positioning device to achieve electrical initial positioning and mechanical accurate positioning, thus ensuring accurate positioning.

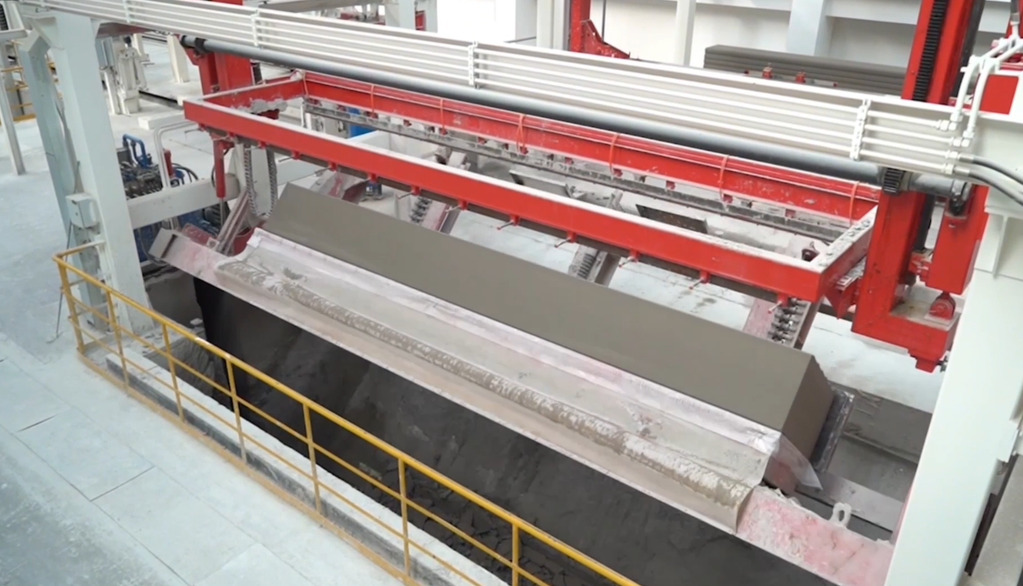

The semi-product tilting machine in the AAC production line is the main equipment for removing the top and bottom layers. Beside the single station semi-product tilting machine, Keda Suremaker has developed a new type of double station semi-product tilting machine, which has the following characteristics: The double station semi-product tilting machine adopts the beam column type air suspension arrangement, and the foundation is the beam frame column, which simplifies the foundation construction of the waste slurry pit below.

The foundation is made into a V-shaped structure to facilitate waste washing. In addition, the L frame of the tilting machine has a hollow design, and the bottom layer of the green cake can fall directly into the waste slurry pit, to avoid the influence of accumulated materials on the positioning accuracy of the bottom plate, and to facilitate daily maintenance and improve the upkeep and cleaning of the workshop. The rotation center of the tilting machine is set near the overall center of gravity to reduce the cylinder diameter, simplify the hydraulic power configuration, and improve the reliability and durability of the tilting main frame. The oil cylinder is suspended in the air to effectively avoid slurry splashing, which would reduce its service life. Double stations are set at the bearing position of the side plate of the double station semi-product tilting machine. The stacking machine lifts a green cake and places it above the tilting machine. At this time, the tilted green cake is moved to the outside. The stacking machine places the green cake in the tilting position, then moves out and lifts the outside tilted green cake away. In this way, the tilting machine can work continuously without waiting, thus improving the operating efficiency and meeting the production requirement of large capacity. The total production efficiency can be controlled within 2.5 minutes.

Currently, the global community is actively addressing the environmental issues caused by carbon emissions, and the construction materials industry is no exception. At the same time, the application of digitalization and intelligence in the construction materials industry is gradually becoming a mainstream trend. As a holistic AAC plant solution supplier, Keda Suremaker is actively collaborating with customers, taking reducing energy consumption, improving efficiency, and reducing carbon emissions as the direction for equipment innovation. Meanwhile, Keda also applies the industrial Internet of Things in production lines and deposits production data. Through continuous technological research and optimization, Keda has successfully helped numerous customers achieve green upgrades of their production lines. In future developments, Keda will work together with global partners to create more low-carbon and intelligent autoclaved aerated concrete production lines.

KEDA SUREMAKER (Anhui KEDA Industrial Co., Ltd) is a holistic autoclaved aerated concrete plant solution supplier from China, providing customers with customized service including production process and formula design, equipment R&D, manufacturing, plant engineering, personnel training, and operation management consulting, etc. In both Chinese market and the overseas AAC market, KEDA has demonstrated its strong momentum. Nowadays, the AAC plants powered by KEDA SUREMAKER have been distributed to Europe, Southeast Asia, the Middle East, South Asia, South America.

As the vice president unit of China Aerated Concrete Association and the associated member of European AAC Association, KEDA SUREMAKER is in charge of editing the China AAC industry standards and is committed to promoting the development of the worldwide AAC industry.

KEDA SUREMAKER Holistic AAC Plant Solution, make sure of your success.

Anhui KEDA Industrial Co., Ltd

2887, Tianmen Rd, Economic & Technological Development Zone, Ma’anshan, Anhui Province

China

www.kedasuremaker.com

info@keda-suremaker.com