ARTICLE

Jiangsu Teeyer Intelligent Equipment Co., Ltd, Changzhou City, Jiangsu Province, China

High capacity AAC block production line commissioned in China

A 20-year collaboration is witness to Teeyer’s great-leap-forward development

As a well-known enterprise in the Chinese autoclaved aerated concrete industry, Huzhou Linghu Lingxin Wall Material Co., Ltd. is one of the earliest manufacturers in the Jiangsu-Zhejiang region to produce AAC products. With a well-established distribution network and a strong product reputation, the company has become an important supplier of AAC in the Jiangsu-Zhejiang and surrounding regions.

The collaboration between the two parties began in 2004. From the first AAC production line with an annual capacity of 120,000 m3 to the current Teeyer standard 6*1.2 m model and the 1 million cubic meter production line, the companies´ collaboration has closely followed the development of China’s AAC industry and its technological advancements, and has supported the flourishing growth of the Chinese AAC market.

Teeyer Intelligent’s long-standing focus on product quality, service capabilities and technological innovation has helped them achieve a leading position in the industry. Lingxin Wall Material’s decision to once again choose Teeyer Intelligent as a partner marks a strong recognition of Teeyer’s brand.

Focusing on R&D to promote industry upgrades

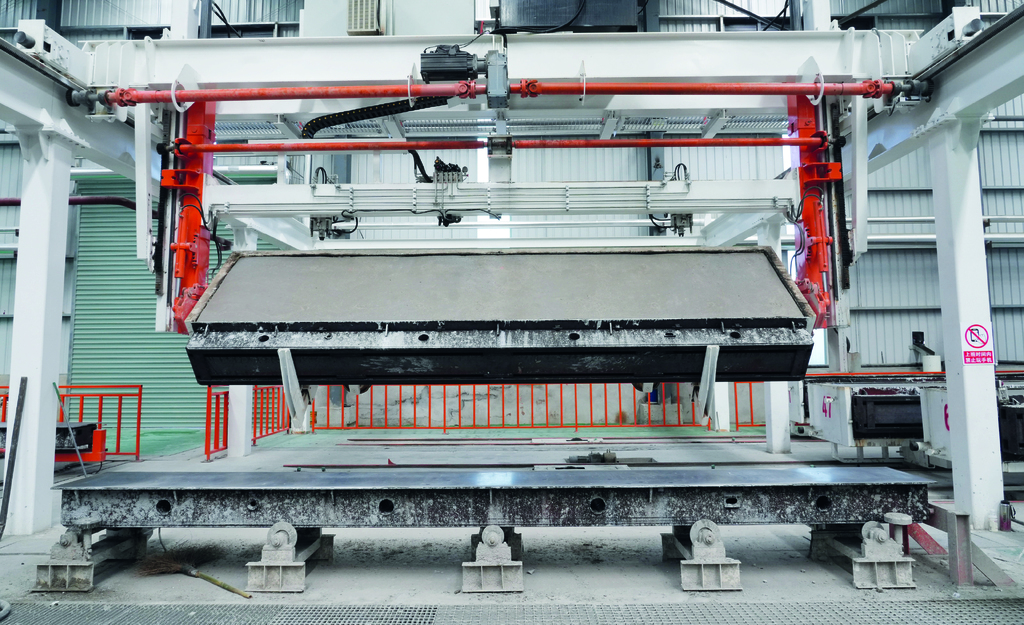

The main highlight of this project is the fact that the capacity of the plant is designed for 1 million cubic meters with just one production line. This is to be ensured by an actual production cycle of less than 100 seconds per mould. Teeyer Intelligent is committed to product research and development, constantly breaking through technological barriers, and combines industry-leading patented technologies with an experienced R&D team.

The project incorporated several innovative designs and product upgrades, as discussed in the following.

Mixer

The pouring mixer is the core equipment of the AAC production line, which was customized by Teeyer based on the client’s demand for high capacity and fast production cycles. The machine features a double-layer paddle design and is driven by a high-power motor for high-speed mixing, combined with high-temperature pouring technology, ensuring efficient and stable operation and outputs of high quality.

Cake-waste-removing station

The cake-waste-removing station is equipped with a new overhead rotation crane, which is fully integrated into the production process, and which provides high functionality. The crane can rotate and remove the bottom layer waste from the cake during the transport process, significantly improving production efficiency.

Automation

To improve the level of automation, a servo control system was configured for the cutting machine. The servo-drive side cutting ensures precise control of the cutting depth for each cutter, making the cutting surface smoother and more uniform. The system also adjusts the cutting position of each steel wire accurately and compensates for material loss, greatly enhancing product dimensional accuracy and reducing errors caused by manual adjustment. The system also includes wire breakage alarms and automatic wire cleaning functions.

In the fiercely competitive market, maintaining product quality is the key factor to ensuring sales growth for Lingxin Wall Material. Teeyer’s R&D team developed a new servo replacement and intelligent hydraulic tensioning system for the project. The flexible control system of the cutting machine ensures high product quality while maintaining the fast production cycle, achieving a very high pass rate of finished products.

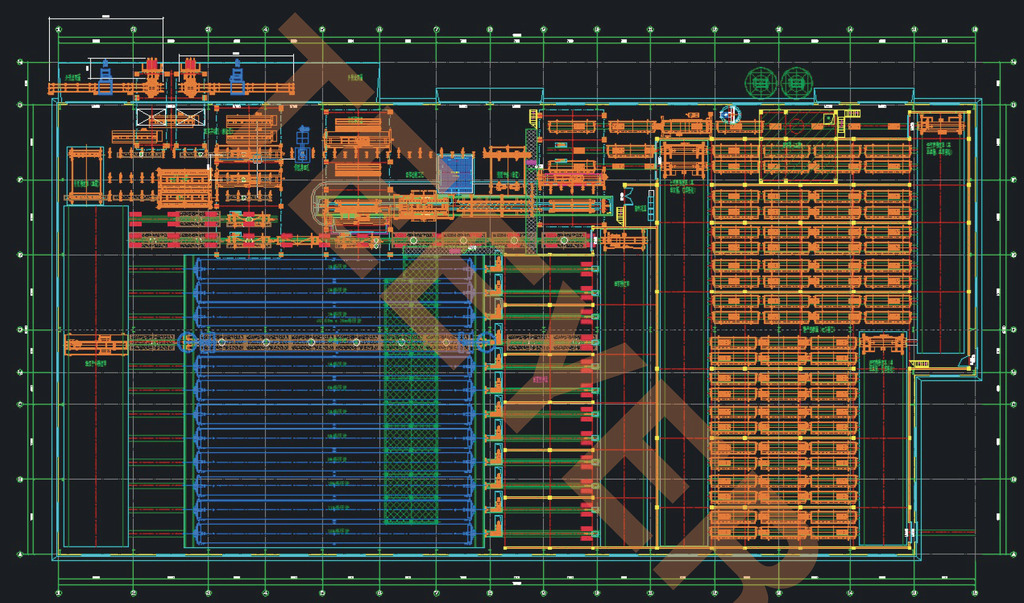

Innovative plant layout and energy saving result in cost reduction and sustainable production

Lingxin Wall Material’s plant is located near water ports, power plants and cement factories, naturally providing transportation convenience and raw material cost advantages. However, the limited land area presented a challenge for the required large-scale high-capacity production line. Teeyer’s R&D team customized the design according to the client’s local situation, maximizing the use of existing land and optimizing investment costs to improve customer benefits.

The pre-curing section uses double-mould synchronous ferry carts and multi-mould positions with friction wheel drives to optimize the pre-curing room. This design minimizes the area occupied by the pre-curing room while extending green cake growing time, ensuring product quality and significantly reducing the use of binding materials, thereby saving production costs.

The innovative short-distance grouping layout of the autoclave section (three cart positions in front of the autoclave and one behind) integrates friction wheel and traction mechanism drives to achieve fast movement of cakes in and out of autoclaves, enabling high capacity and quality production while minimizing space and investment.

The entire production line uses servo-driven systems for transporting green cakes, improving positioning accuracy and speed control to quickly respond to input signals, ensuring efficient equipment operation and reducing energy consumption.

The entire production line uses a hydraulic servo system, capable of responding to system flow within milliseconds, ensuring precise and efficient operation. The system provides precise and rapid control, achieving energy savings and reducing waste, while also improving oil temperature control, seal life, ambient noise development, and hydraulic accuracy.

The project had a tight construction schedule, with the production line being fully operational within six months of signing the contract. The equipment shipment, installation, commissioning, and commencement of production took only three months, saving the client significant time-related expenses and demonstrating Teeyer Intelligent’s high project execution capability, earning high praise from the client.

Founded in 1989, Teeyer Intelligent always advocates a pragmatic, professional, innovative, win-win business philosophy. To date, over 1,200 AAC panel & block production lines have been built by Teeyer, exported to more than 20 countries and regions worldwide. On October 23, 2023, the company successfully registered on the Shanghai Stock Exchang.

((QR-code))

See a video of the Huzhou Linghu Lingxin Wall Material Co., Ltd. high-capacity plant in operation.

Jiangsu TEEYER Intelligent Equipment Co., Ltd, is located in National High-tech Development Zone in Changzhou City Jiangsu Province. It is a R&D and manufacturing enterprise specializing in complete sets of equipment and production lines for autoclaved aerated concrete machinery. The leading products include complete sets of AAC cutting equipment, AAC panel equipment and Engineering machinery.

TEEYER was established in 1989 with a registered capital of 160.7 million yuan, an area of 143,000 square meters, and over 400 employees. TEEYER has a provincial-level enterprise technology center with more than 80 R&D personnel. TEEYER conducts extensive industry-university-research cooperation, with no less than five research and development product projects and no less than 20 patents declared each year.

This Teeyer channel and all information presented here is provided by AAC Worldwide - the journal for the Autoclaved Aerated Concrete industry. All articles about Teeyer are available for free. Feel free to share information from this website with other industry professionals!

Jiangsu TEEYER Intelligent Equipment Co., Ltd.

NO. 312, West Hehai Road, High Technology

Development Zone, Changzhou City, Jiangsu Province, China

Postcode: 213125

T +86 13861131181

sales@teeyer.com

www.teeyer-global.com