ARTICLE

Jiangsu Teeyer Intelligent Equipment Co.,Ltd, Changzhou City, Jiangsu Province, China

Modern plant equipment to meet customer requirements

Topics related to carbon emissions have attracted global attention and are discussed in an increasing number of countries worldwide. At present, it is increasingly necessary to promote green development of urban and rural construction, to vigorously develop energy-saving and low-carbon buildings, and to accelerate the optimization of energy consumption of buildings. The carbon footprint of the construction industry is a key parameter in achieving a low overall national carbon footprint. In this regard, China's AAC market has a huge potential for making a significant and positive difference.

Material recycling and energy saving

With the rapid development of the construction industry, more efficient and more intelligent all-round one-stop services becomes increasingly popular. Teeyer will now introduce their technology and services to one of the most prominent and latest construction projects in the East China region: Taizhou Jintai Environmental Protection Thermal Power Co., LTD.

Considering material recycling and energy saving, Teeyer installed an integrated collection device at the top of the vertical cutting machine and a dry material conveying device under the tilting table, to ensure the efficiency of waste recycling. Compared with the previous set-up, this change will avoid the slurry splash phenomenon during the process of tilting and provide a better working environment. In addition, it will assist in improving the stability of equipment operations.

Reduction of production cycle times

The cake auto-shifting technology of the tilting table solves problems including reciprocating crane operations and long-time waiting times for the handling of the cake. It greatly improves the production efficiency of the whole line – the production cycle is shortened by 1 min/mould - and improves the cutting section. The overall production capacity is increased by 25%.

The trolley adopts a wheel-rail movement mode to achieve precise positioning and is driven by a hydraulic system. The accurate rail alignment between the mounted track, the bridge trolley track and the autoclave track ensures stable operating conditions of the autoclaving ferry cart.

Optimizing steam generation, management, and usage

The autoclave steam distribution system requires less skills for operators and the operation is quite simple. Operators only need to close the door of the autoclave, then select functions on the computer in accordance with a predetermined solutions (e.g., block type, thin panel type, thick panel type), and press a button to start the corresponding autoclave number. The system also improves the security of the steam distribution. A safety interlocking procedure is provided between the steam distribution valve and the autoclave door opening device, with an extra light alarm device. If the door is not closed well, steam will be prohibited to enter, and as long as steam is present, the door cannot be opened.

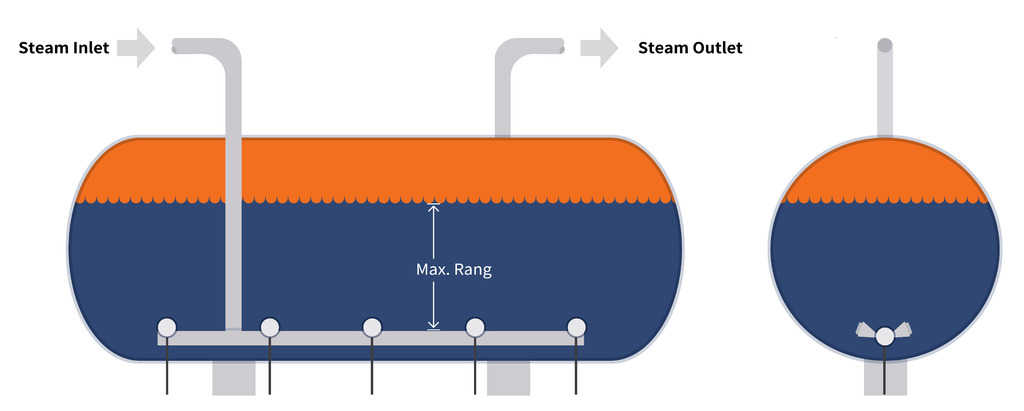

In the normal continuous cycle operation of the autoclave, the autoclave residual steam recovery system can recover all the steam from pressures of 0.55 MPa to 0.00 MPa. The steam recovered from 0.55 MPa to 0.15 MPa can be returned to the autoclave, while the steam below a pressure of 0.15 MPa is used for the heating system and boiler soft water heating.

The steam recovery system of the autoclave adopts the heat accumulator equipment to recover and store the steam. When the steam that enters the accumulator equipment returns to the autoclave, the ratio of the exhaust steam volume to the intake steam volume of the accumulator group can reach more than 95%. In the final stage of the exhaust steam process, the exhaust speed slows down due to the decrease of the steam pressure, which affects the efficiency of the autoclave. When the steam pressure reaches 0.15 MPa, the method of steam pumping can increase the steam exhaust speed, instead of emitting the steam to the environment. This technology not only contributes to the purpose of energy saving and carbon reduction, it also reduces waste steam emissions and therefore assists in protected our environment.

Residual steam recovery

The residual steam recovery system can be linked with the automatic steam distribution system to create an automatic operation and reduce or eliminate the need for staff involvement. After adopting the autoclave residual steam recovery system, the autoclave energy saving index reaches more than 20% (the energy saving index refers to the ratio of the steam quantity supplied by the accumulator to the fresh steam quantity directly used in the autoclave). During autoclaving, the real fresh steam requirement is less than 110 kg/m³ for panels and 105 kg/m³ for blocks.

The hot water from the residual steam recovery system can be used to maintain a regulated environment in the pre-curing room and the steel bar drying room, without using fresh steam. The temperature of the pre-curing room is at around 40 - 50℃ and the temperature of the steel drying room is at around 50 - 60℃, assuming an ambient temperature of 20℃. If necessary, the softening water required by the boiler can be preheated.

The residual steam recovery system can also facilitate the utilization of condensed water that is discharged from the autoclave. At the high temperature stage, the heat in the condensed water is recycled for heating the preconditioning room and the curing room before autoclaving.

With the continuous development of technological innovations, efficiency and reliability have nowadays become the main concerns of customers. Teeyer will always focus on the needs of their clients, to provide them with a reliable, cost-effective and all-round one-stop service.

Jiangsu TEEYER Intelligent Equipment Co., Ltd, is located in National High-tech Development Zone in Changzhou City Jiangsu Province. It is a R&D and manufacturing enterprise specializing in complete sets of equipment and production lines for autoclaved aerated concrete machinery. The leading products include complete sets of AAC cutting equipment, AAC panel equipment and Engineering machinery.

TEEYER was established in 1989 with a registered capital of 160.7 million yuan, an area of 143,000 square meters, and over 400 employees. TEEYER has a provincial-level enterprise technology center with more than 80 R&D personnel. TEEYER conducts extensive industry-university-research cooperation, with no less than five research and development product projects and no less than 20 patents declared each year.

This Teeyer channel and all information presented here is provided by AAC Worldwide - the journal for the Autoclaved Aerated Concrete industry. All articles about Teeyer are available for free. Feel free to share information from this website with other industry professionals!

Jiangsu TEEYER Intelligent Equipment Co., Ltd.

NO. 312, West Hehai Road, High Technology

Development Zone, Changzhou City, Jiangsu Province, China

Postcode: 213125

T +86 13861131181

sales@teeyer.com

www.teeyer-global.com