Application & Construction

Large-scale panel application

Lighthouse projects of the Chinese AAC construction industry

Loading...The PKX project started construction in December 2014 and officially opened to traffic in September 2019. The terminal covers an area of 780,000 m2 and has a throughput of 250 million passengers. A total of 12,000 m3 of AAC panels were used in this project. It was named the first of the "Seven Wonders of the Modern World" by the British "Guardian", in addition to world-famous buildings such as the Saudi Kingdom Tower and the Hong Kong-Zhuhai-Macao Bridge.

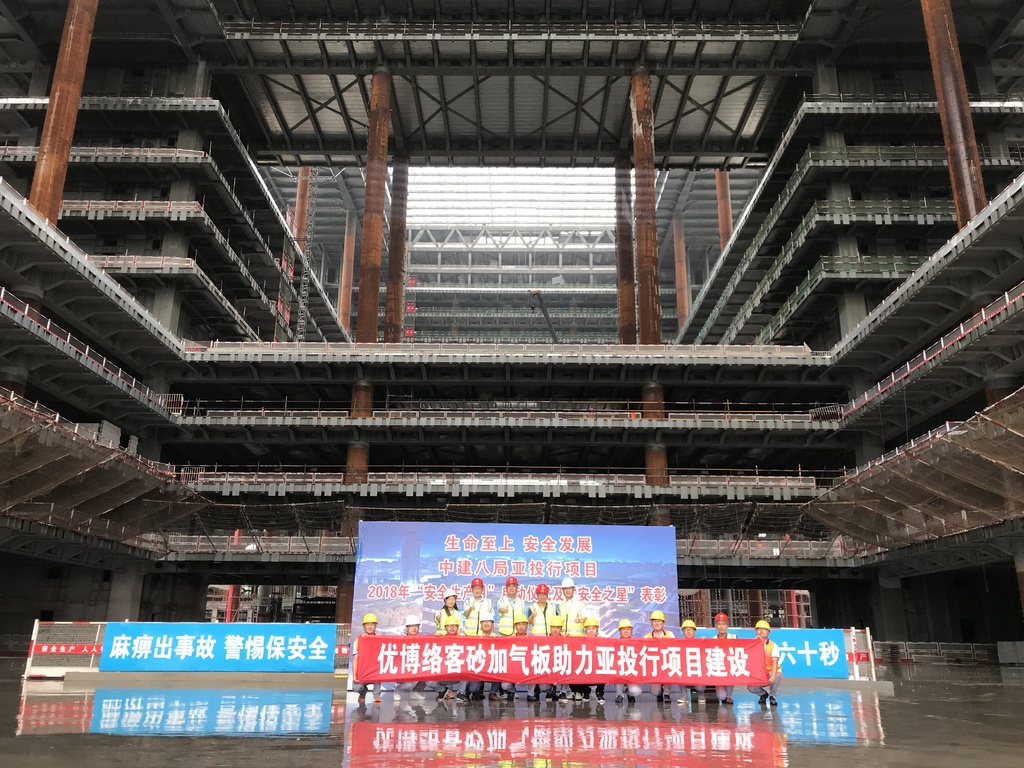

The HQ of AIIB was officially put into use in January 2016, with a construction area of 250,000 m2. In accordance with the core concept requirements of green construction pursued by AIIB, AAC panels were selected as construction materials, following multiple rounds of selection and expert reviews. A total of 3,000 m3 of AAC panels were used in this project.

AAC has the advantages of thermal insulation, sound insulation, light-weight properties, relatively high strength, fire prevention, recyclability, etc., and has become the state-of-the-art wall material vigorously developed and promoted in China. AAC panels are suitable for internal and external walls, floors, roofs, firewalls, etc., for both concrete and steel structure buildings, residential buildings, office buildings and workshops, and has become a mainstream material of choice for prefabricated buildings.

The advantages of AAC panels are plenty - AAC panel dry densities of 400-625 kg/m3 can significantly reduce the building weight, the fire resistance limit of a 100 mm thick panel can reach more than 4h, a thermal conductivity of less than 0.16W/(m·K) can be achieved, AAC panel production can follow the principles of industrialization and standardization, the installation can be industrialized to provide simple and fast construction and AAC panels can greatly shorten the construction period and reduce labor and equipment related costs.

AAC panels can be divided into vertical and horizontal panels according to the installation method. The main methods of connecting AAC panels to concrete and steel members such as beams and columns are the hook head bolt method, the sliding bolt method and the built-in anchor method.

The inner wall panels of the prefabricated structure are mainly divided into partition walls. The main advantages of assembled interior wall panels are high strength, environmental protection, low cost, high construction efficiency, sound insulation and fire resistance. AAC inner wall panels have the two main forms of vertical panels and transverse panels. AAC floor panels are mainly connected by the U-shaped clamp method, straight angle steel, the pipe clamp method, or the hook head bolt method.

AAC panel installation process

Installation sequence

The panel should be installed from the door and window openings to both sides, and the entire panel should be installed on both sides of the door. Wall sections above doors and windows should be sequentially installed after the wall panels are cut into corresponding dimensions. For walls without doors and windows, panels should be installed sequentially from one end of the main structure to the other. When the width of the wall panel at the intended installation site is less than one whole panel, the panel should be cut, and the width should be greater than 200 mm.

During installation, the wall panels should be pressed against each other, and the wall should be adjusted to be in a flat and vertical position. Once the outcome of the inspection meets the requirements, the gap in the lower part of the wall is temporarily fixed with a wooden panel and packed with C20 fine aggregate concrete. Generally, after three to five days, the wooden panel can be pulled out and the space sealed with fine aggregate concrete of the same strength.

Joint treatment

The joints between wall panels and structural concrete members, and the joints between the individual wall panels, should be filled with a special joint agent, pressed into alkali-resistant glass fiber cloth, and scraped flat with anti-crack putty.

The two lighthouse projects mentioned above have impressively demonstrated that AAC panels are ideally suited for the construction of large-scale projects. The advantages that result from the material properties and which manifest themselves in the construction progress provide important arguments for the massive use of AAC panels in the Chinese construction industry. This trend has been going on for several years now and there is currently no end in sight.

UBlok company is one of the largest AAC panel manufacturers in the country and prides itself on providing great value-added building materials to China's construction industry.