Production Technology

Masa WhiteHub, 32457 Porta Westfalica, Germany

AAC panels – Part 2: From reinforcement to packaging with integrated solutions

Loading...The equipment includes a Cutting Line that can be expanded with the specialised Masa Lintel Cutter, designed for producing lintels with the required heights. The setup may also incorporate additional autoclaves with differentiated process parameters tailored to the geometries of the panels, along with advanced Laboratory Systems for mechanical testing – particularly for evaluating compressive and shear strength. Special attention is also given to the technical challenges of a panel-specific Packaging Line.

Precision meets versatility: Cutting technology for all sizes and types

Just as for AAC blocks, the mould with the green cake with reinforcement is transported to the mould turning manipulator. The manipulator demoulds the cake and transfers it to the cutting line, ready for processing.

First shaping

In the initial shaping stage, cutting wires and specially designed smooth-cutting knives trim the green cake to the required sizes.

Optionally, tongues and grooves can be produced in one step by means of profiling knives. This helps to generate particularly smooth and precise tongues and grooves. The pattern can quickly be changed with a simple changing system.

As for cutting blocks, the process begins with a pre-cutter that removes the large sides of the cake. This is followed by a vertical knife system – also known as the profiler – which reduces the gross cake to its net width and cuts the desired profiles into the sides. If no profiling is needed, the cake is cut to a smooth net width of 600 mm. If profiling is required, with a tongue-groove profile, the cut will take the size of the tongue into account.

Each profile type and size require its own dedicated knives, which are supplied with the reinforcement line. The customer determines the desired profile design. A calibration jig allows the operator to verify and precisely adjust the knife settings to achieve the exact profile dimensions. The unit’s straightforward setup ensures that the profiles on both sides of the panels align perfectly.

At the end of the cutting line, air blowers powered by compressed air effectively remove residual cutting waste. This is especially recommended for floor and roof panels, where deep grooves may retain waste material, and is highly advisable in the production of reinforced products. If the sum of the lengths of the reinforced products to be produced in a single mould deviate significantly from the standard mould length (6 m), leading to inefficient mould usage, there are two possible solutions:

Use of dividers like the Masa Bulkhead System: The mould can be partially filled, casting only the section intended for reinforced products.

Full mould usage with partitioning: The entire mould is filled, but only the first section is used for reinforced products. The remaining section is cut into blocks.

In the latter case, the profiler can be equipped with retractable knives (and blow devices). When the green cake enters the profiling unit, the knives are in position and perform the profiling required for the panel section. Once the panel section has passed, the knives automatically retract, allowing the remaining part of the cake to be cut into blocks without profiling. This system enables full utilisation of the mould, ensuring maximum production efficiency.

Defining the wall thickness

After trimming the long sides and applying the profiles, the cake is transferred to the horizontal cutter, which separates it into individual panels.

Short, pneumatically tensioned cutting wires precisely slice the cake into up to 30 layers, each corresponding to the final wall thickness. The product dimensions can be adjusted in 5 mm increments, ranging from 50 mm to 500 mm.

Defining the final shape

With oscillating movements, short, pneumatically tensioned wires precisely cut the green cake to the required panel length (for blocks, it will determine their height). This machine, known as the cross cutter, is equipped with an integrated vacuum unit that removes the top layer (the top crust) and returns it to the slurry recycling system.

Nothing wasted

To save raw material resources, all waste material accrued throughout the complete cutting process is collected, processed, and returned to the production process. The rinsing water from the mixing plant is mainly used for this.

After the cutting process, a hydraulically operated back tilting table swivels the cake back into its horizontal position. This ensures that the cakes can enter the autoclaves horizontally and also enables removal of the bottom crust, which is returned to the slurry recycling system. As a result, only the net usable green cake is hardened, significantly reducing waste and improving overall plant efficiency.

Cutting lintels in the green state: Efficient, precise, and compact solution

For lintel production, an additional station – the Lintel Cutter – is positioned after the back-tilting table and before the optional green separator.

After the cake processed in the cutting plant is tilted back, oscillating wires cut the lintel to the desired processing height. The standard dimensions here are 200 mm and 250 mm. However, considering the built-in steel reinforcement, individual height dimensions can also be freely selected.

The wire position can be adjusted in 5 mm increments and offers high manufacturing precision. The controllable oscillating movement prevents damage to the lintels when the wire exits.

The lintel cutter is integrated into the production process and therefore does not extend the cycle time. Thanks to its compact design, it can be retrofitted to most AAC plants after the tilting table. Compared to dry cutting of the lintels after autoclaving, the energy required for cutting the still green lintels is significantly lower. This leads to a reduction in energy costs. Another advantage is that no dust is generated when cutting the green lintels, which means that the otherwise essential dust extraction system with a suitably designed filter system is not required.

Optimal hardening process for panels

The autoclaving cycle for reinforced AAC elements differs from that of standard blocks. While a full cycle for blocks, including loading and unloading, takes about 12 hours, reinforced products require around 15 to 16 hours. This is due to their higher density, which slows steam penetration. Additionally, the presence of steel with its different rate of expansion requires slower pressurisation and depressurisation to avoid cracking. The exact duration may vary depending on the reinforcement applied, the dimension of the elements and the density.

When it comes to determining the number of autoclaves required, there are essentially two strategic options, depending on the producer’s objectives:

The producer may choose to maintain the existing number of autoclaves used for block production, accepting a reduced output of reinforced products as a result.

Alternatively, the producer may define a target production volume for reinforced products and be prepared to expand the number of autoclaves and related equipment to meet that goal.

Specialised handling and packaging of lintels and panels

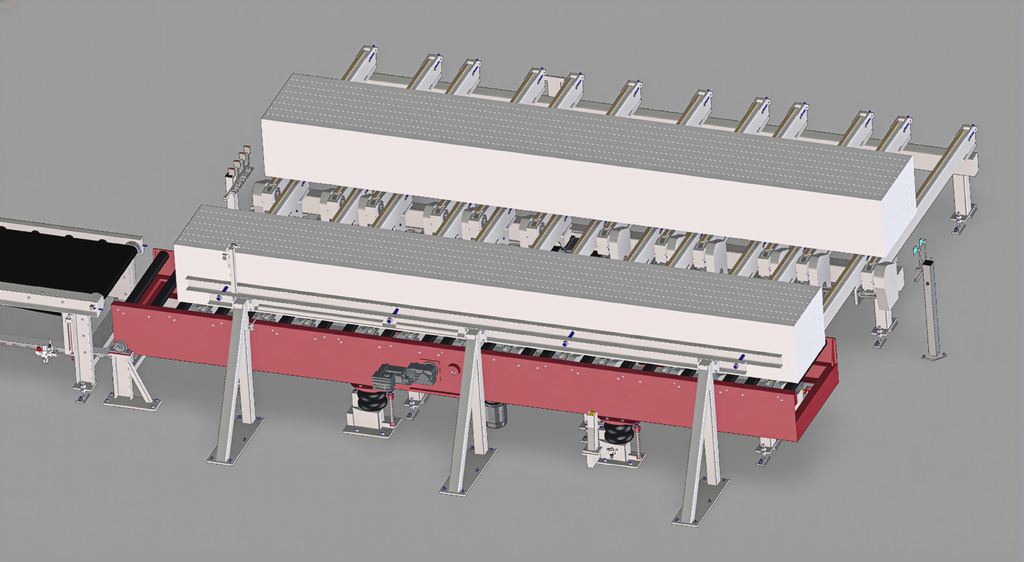

Usually, in parallel to the packaging line for blocks, a separate packaging line is set up for the reinforced products, including:

Panel unloading system for treating the panels individually (if required) and on edge

Options for partition walls for grouped handling and packaging

Options for other panels for individual handling and packaging

Panel unloading system

A specialised unloading system enables automated, individual handling of the panels. The unloading manipulator places the hardened (white) cake containing the reinforced elements directly onto the panel unloading system. This system consists of a series of conveyor belts that transport the white cake to a designated position for strapping and unloading. Each cake contains multiple panels. The system can separate these into individual panels or customised groups for flexible handling. All panel groups can be manually strapped if required.

Options for partition walls for grouped handling and packaging

Partition walls are non-load-bearing elements used to divide interior spaces into separate areas. Typically installed floor-to-ceiling as storey-high panels, they range from 2.6 to 3.0 meters in length, allowing for two groups of panels to be produced sequentially in a mould. Due to their function, they are made very thin – usually 100 to 150 mm. Depending on the thickness, approximately 20 to 30 panels can be produced per mould (e.g., 2 × 10 panels at 150 mm or 2 × 15 panels at 100 mm).

Since multiple panels are required per floor and they are relatively lightweight, customers prefer grouped delivery to the site. This approach minimises the risk of damage during handling and transport and improves efficiency on-site.

To meet these needs, Masa WhiteHub offers automated packaging solutions. One common method is to strap or wrap all panels from a single mould (the complete “white cake”) together. As autoclaving in Masa WhiteHub plants is done horizontally, the panels are laid on their side and can be secured with two to three vertical straps or fully wrapped in plastic film, providing protection against moisture and weather exposure.

Alternatively, smaller groups of five to ten panels can be packaged, depending on customer preferences and logistical requirements.

Masa WhiteHub’s range of grouped packaging options ensures safe and efficient handling of partition walls at every stage of the process, from production and storage to transport and on-site installation.

Options for other panels for individual handling and packaging

In addition to the flexible separation and grouping of panels, Masa WhiteHub offers another special feature specifically for floor and roof panels.

Since these panels are installed flat in buildings, delivering them in a horizontal position greatly simplifies on-site handling. They can be clamped directly from the transport pallet and lifted into place without additional repositioning. To facilitate this, a specially designed tilting table is used: upright panels are loaded onto the table by a forklift, which then gently tilts them into a flat position. This solution is both practical and efficient.

Tailor-made AAC panels for maximum on-site efficiency

The panels produced according to the above-mentioned process are used as precast elements, significantly accelerating assembly on the construction site. To further enhance efficiency, these elements can be fully customised in shape and dimensions to match their exact installation location – including the option for sloped or angled edges.

To achieve these special geometries, Masa WhiteHub offers fully automated cutting systems. These systems start with standard rectangular AAC panels and transform them into precisely tailored end products that are ready for immediate use on-site – no further adjustments required.

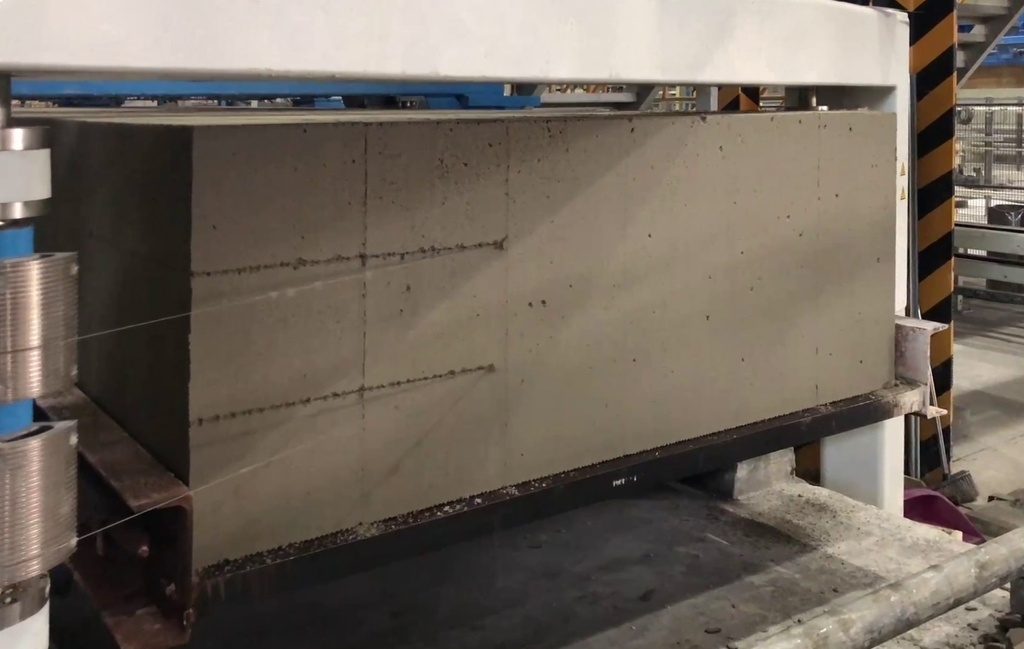

Advanced testing for reinforced AAC panels

In addition to the standard laboratory equipment required for AAC block production, manufacturing reinforced panels demands further testing capabilities.

Specifically, equipment is needed to analyse the properties of the reinforcement steel used. More importantly, since load-bearing panels form part of a building’s structural system, the manufacturer – together with the architect and structural engineer – must ensure that the panels meet all applicable strength requirements.

This involves more than just structural calculations. The manufacturer must also provide proof that the produced panels meet the specified strength requirements. To do so, destructive testing on full-size panels is necessary to confirm that the actual strength aligns with the calculated values.

Masa WhiteHub offers the required testing equipment for such destructive tests, including systems for data storage and analysis.

It is important to note that most countries have specific standards and regulations governing these requirements. Therefore, customers are strongly advised to familiarise themselves with the relevant national guidelines and ensure full compliance.

Where theory meets practice: AAC panel production plant set for launch in 2026

In Saudi Arabia, a unique Masa WhiteHub AAC plant is currently taking shape, featuring a separate, fully automated area dedicated to the production of reinforced panels. The plant is expected to begin operations in 2026.

Well before the start of the intensive technical planning and design phase, numerous coordination meetings between Masa WhiteHub and the customer ensured that all requirements were thoroughly understood and fully incorporated into the project. The production of individual plant components at the Porta Westfalica site has been completed, and shipping is nearly finalised.