Production Technology

UKeyer Intelligent Equipment (Zhejiang) Co., Ltd., 313000 Huzhou, China

Case studies – AAC block production line upgrading to panel production

Loading...Background of the factories that were transformed

Changxing UBlok Factory (formerly Ytong Factory) is located in the Yangtze River Delta Economic Zone of China, with its market covering major cities such as Shanghai, Hangzhou and Suzhou. Built in 2007 as an Ytong autoclaved aerated concrete block production line, the factory has an annual production capacity of 400,000 cubic meters. It was fully acquired by UBlok in 2019.

Tianjin UBlok Factory (formerly Xella Factory) is located in the Beijing-Tianjin-Hebei region of China, primarily serving markets in Beijing, Tianjin and Hebei. Built in 2008 as a Ytong AAC block production line, the factory has an annual production capacity of 400,000 cubic meters. It was fully acquired by UBlok in 2017.

Differences between the transformed factories

Differences in basic conditions

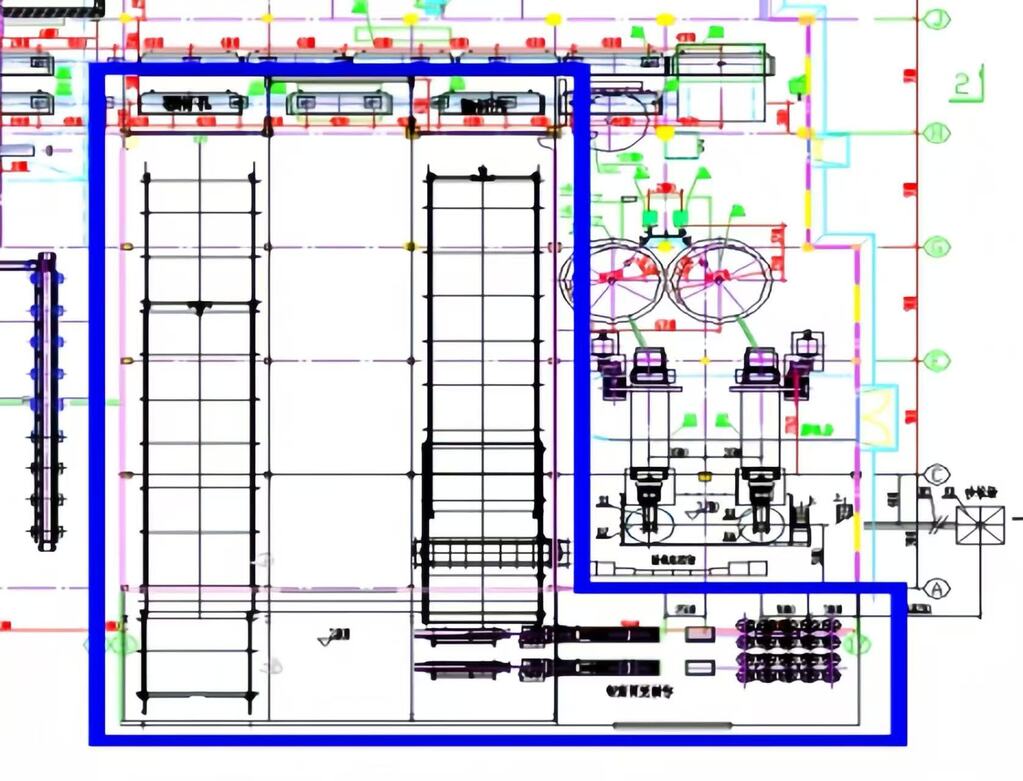

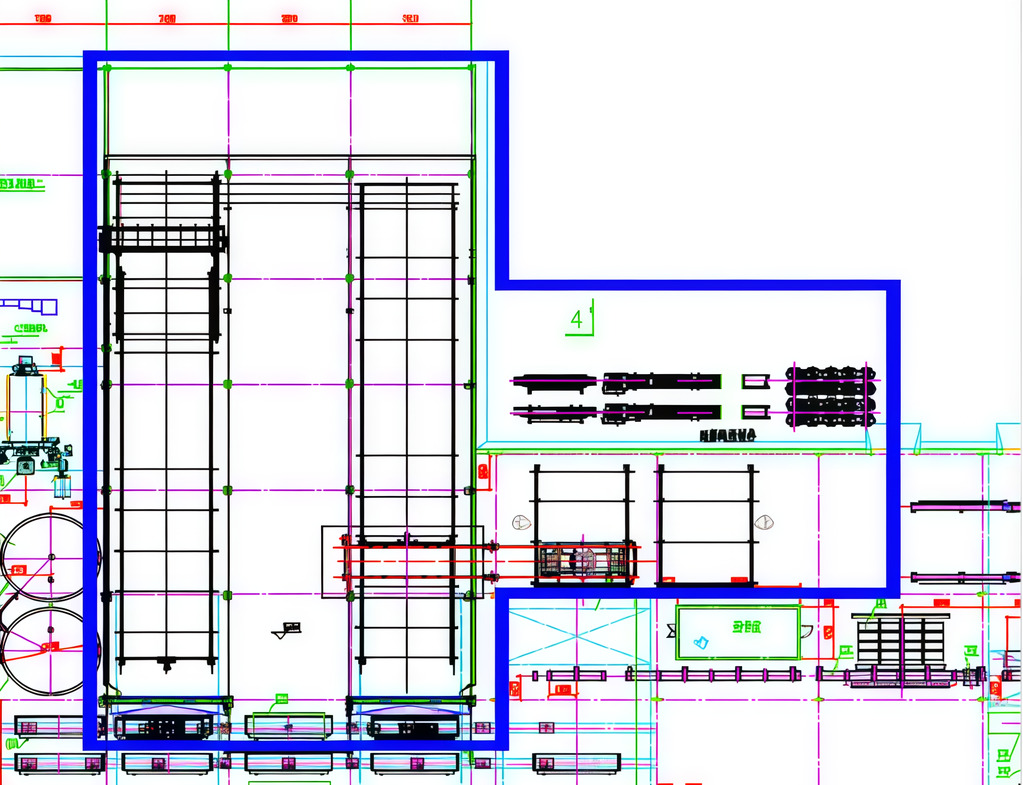

There are certain differences in the spatial conditions in the above-mentioned two factories, which relates to a common issue faced by most of UKeyer’s factories requiring upgrades for panel production. The main additional equipment for panel production is the reinforcement cage circulation system. Typically, a three-dimensional space to arrange the reinforcement cage circulation system is utilized, and the at the mould static stopping position on the second floor platform is the optimal location. The second-floor space of the Tianjin factory covers an area of about 1,200 m², and the Changxing factory's second floor has a size of about 1,600 m². The available space in both projects could not meet the process layout requirements according to standard design. Therefore, UKeyer adopted different process layouts to meet the requirements for upgrading the facilities for panel production. The Tianjin factory uses hanging nets and circulation drying with underground and floor-level cycles. The Changxing factory uses double-layer drying conveyance in combination with multi-layer storage to solve the problem of insufficient space.

Product specification differences

The market served by the Tianjin factory has high demand for products used in the construction of public buildings, as well as stringent requirements for thermal insulation and energy efficiency. The market served by the Changxing factory has strong focus on residential and warehouse/industrial buildings.

Factory upgrade for panel production

In 2015, the Changxing factory underwent modifications to the cage circulation system and cutting system, initially gaining panel production capability with an annual output of less than 100,000 m³. After acquisition by UBlok in 2019, the number of autoclaves was increased to nine, alongside modifications to the autoclaving and drainage systems, enabling the production of fair-faced wall panels and thin panels (less 100 mm thickness). In 2021, the slurry preparation system was optimized, a green bottom layer removal and dry recovery system via conveyor belt was added, and production scheduling software was launched. In 2022, the automatic panel packaging system was modified. In 2023, the cutting system was optimized, achieving mass production capability for thin panels with widths below 100 mm. A year later, the digital warehouse management and IOT were launched.

Tianjin Factory underwent panel system modification in 2016, achieving an annual panel production capacity of 200,000 m³. In 2020, the cage circulation system was upgraded again, reducing the production cycle time to less than 3.5 min/mould. In 2021, the slurry preparation system was optimized, a green bottom layer removal and dry recovery system via conveyor belt was added, and production scheduling software was launched. In 2024, the automatic panel packaging system was modified while the cutting system was also optimized.

Main technical features of the two factories

The main features of the production facility upgrades can be summarized as follows:

1) In-house development of large-cycle process for reinforcement cages

2) Introduction of non-rotation pin technology

3) Thin panel cutter, separation and splitting technology

4) Process technology for fair-faced wall panels

5) Dry method bottom layer removal and recovery process (conveyor belt without pit)

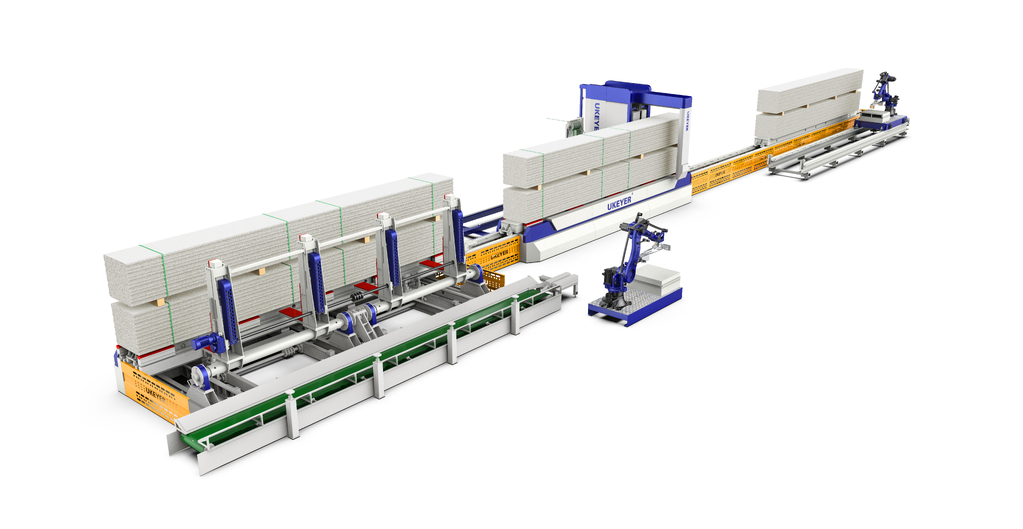

6) Inline panel packaging and turning technology

Journey towards upgrading traditional block lines for panel production

Panels are not equal to blocks plus reinforcement cages. A systematic upgrading according to panel production processes workmanship is required.

Process re-engineering

The following steps were involved in the re-engineering of the production processes:

· Adjusting raw material composition and slurry preparation processes according to panel production needs.

· Commissioning equipment required for integrating a panel production section into the block production line.

· Adjusting to static stopping, cutting, autoclaving, and packaging processes.

Equipment technology upgrade

The upgrades to equipment technology included the following:

· Raw material pre-treatment system to ensure slurry quality.

· Pouring system upgrade to control pore structure and aeration quality.

· Improvement of mould and side plate positioning accuracy.

· Cutting machine modification to improve cutting accuracy, eliminate thin panel settling and edge breakage issues.

· Autoclave control and drainage system upgrade.

· Finished product separation machine modification.

· Finished product packaging system modification.

Management system transformation

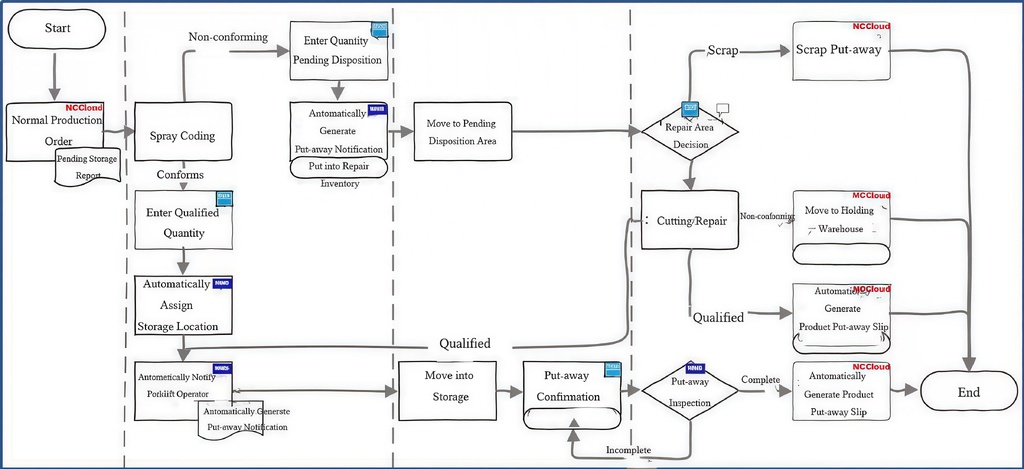

The shift from the block production model to customized panel production required changing the operational method from process manufacturing to a hybrid process consisting of process manufacturing and discrete manufacturing modes.

Digital production scheduling technology was applied to improve moulding rates and production efficiency.

The optimization of quality control levels included several aspects, including quality control of reinforcement cage manufacturing, accuracy control of reinforcement cage cover, strength control of reinforcement cages, quality control of reinforcement anti-corrosion layers, cutting accuracy control, autoclaving quality control, offline warehousing quality control, ensuring first-pass quality yield >97%, secondary repair quality control, and ensuring incoming quality rates of 100%.

The digitalization of warehouse management was implemented according to the characteristics of multi-variety panels, small production batches, and customized requirements. This enabled accurate inventory management through digital warehouse management, adhering to the FIFO principle, as well as achieving efficient inbound/outbound operations and effective utilization of warehouse space.

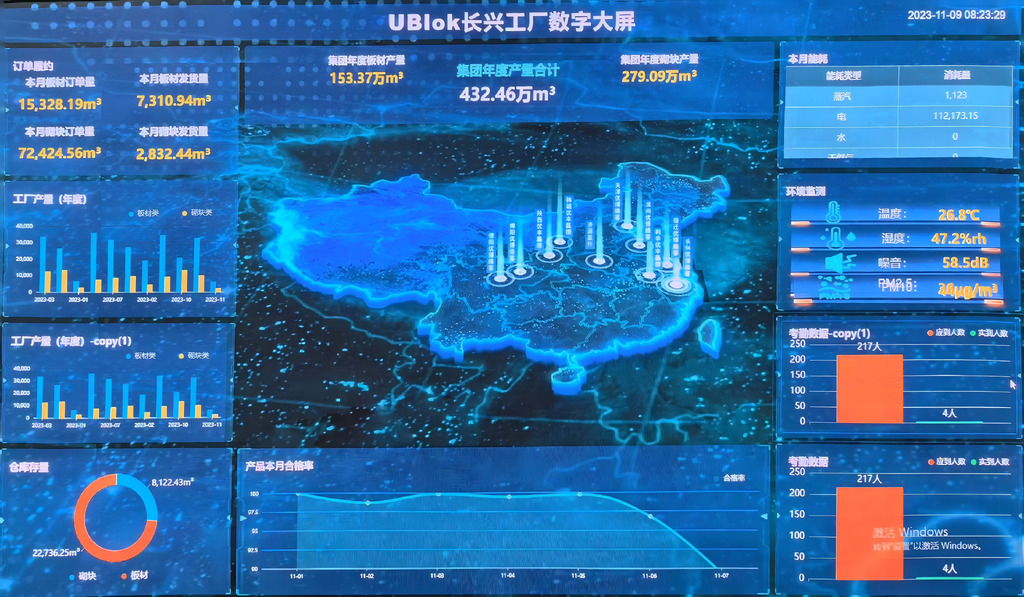

Equipment lifecycle management and energy consumption control were adopted to achieve equipment OEE (Overall Equipment Effectiveness) and low-carbon operation of the AAC factories. Currently, both factories have implemented full IOT connectivity for equipment, enabling fault prediction, fault recording, and full lifecycle management. Water, electricity and steam are fully monitored and analyzed online.

Achievements following the upgrades to panel production

Currently, the panel production at UBlok Tianjin and Changxing factories achieves a moulding rate exceeding 85%, a production cycle time of less than 3.5 min, a first-pass yield larger than 97%, a steam consumption per unit product of less than 100 kg, and single-line daily panel output larger than 1500 m³. Besides continuously improving in aspects such as quality enhancement, efficiency, and cost control, the UBlok plant engineers are also researching and developing higher performance applications for AAC products through technological innovation, aiming at sustainable development of low-carbon, high-quality AAC.

Both factories face a common challenge: having been built nearly 20 years ago, the hardware of their automation control systems has aged, and components have undergone generational changes. This has resulted in increased failure rates, higher maintenance costs, and lower efficiency in troubleshooting. As a result, the UBlok management is planning a comprehensive upgrade of the control systems.

Conclusion

UBlok strives to promote the development of AAC panels toward superior performance and smarter production. This includes deep integration with BIM technology and the development of multifunctional composite panels (such as integrated decorative and insulation boards).