Production Technology

Shandong Dabo Pump Science and Technology Co., Ltd., Boshan District, Zibo, Shandong, China

Innovative Grinding Device: Key Technology for Improving AAC Surface Quality and Waste Material Recycling

Loading...Industry Pain Points and Environmental Protection Needs

At present, many AAC production plants are facing two major challenges:

1. Surface Quality Defects: During the cutting of green bodies, large particles and impurities in the slurry are prone to being dragged and scratched by cutting wires, resulting in scratches and surface unevenness. This affects both the aesthetic appeal and structural consistency of the products.

2. Waste Management Difficulties: Traditional disposal methods for waste products after autoclave curing and demolition waste are often costly, inefficient in terms of resource utilization, and can easily lead to resource wastage and environmental burdens.

R&D Process

In response, the DML-type grinding device was developed with the goal of improving product surface quality while promoting the resource recycling of waste materials, helping companies achieve a win-win situation for both economic and environmental benefits. Over three years, Dabo Pump designed and developed it from the following aspects:

1. Requirement Analysis: Identify market demands, technical specifications, and cost targets, and produce the Product Requirements Document.

2. Conceptual Design: Generate and evaluate design concepts, complete functional structure sketches, and conduct feasibility assessments.

3. Detailed Design: Perform 3D modeling (using software such as SolidWorks or UG), conduct simulation analyses (strength/kinematics), and generate engineering drawings.

4. Prototype Manufacturing: Process and assemble sample components to validate structural rationality and process feasibility.

5. Testing and Optimization: Conduct performance tests (load/lifespan) and reliability trials, iteratively refining the design.

6. Process Finalization: Develop production process documentation, complete small-batch trial production and certification, and transition to mass production.

Finally, the DML-type grinding device was introduced, aiming to enhance the quality of slurry from the source and achieve the recycling of waste materials, providing a practical solution for improving the quality and efficiency of AAC production as well as supporting sustainable development.

Product Introduction: Innovative Design, High Performance

Table 1: DML Grinding Device Model Specifications

Model | Production Capacity

| Grinding Disc Speed (r/min) | Grinding Disc Adjustment Clearance (mm) | Feeding Method | Variable Frequency Motor Power (kw) | |

Liquid | Solid | |||||

DML-33A | 30-50 (m³/h) | ≤ 960 | 0-10 | Backflow | 6-15 | / |

DML-45A | 50-80 (m³/h) | ≤ 700 | 0-10 | Backflow | 6-37 | / |

DML-60A | 70-100 (m³/h) | ≤ 650 | 0-10 | Backflow | 6-55 | / |

DML-60 | 8-15 (t/h) | ≤ 650 | 0-10 | Silo | / | 6-55 |

Working Principle

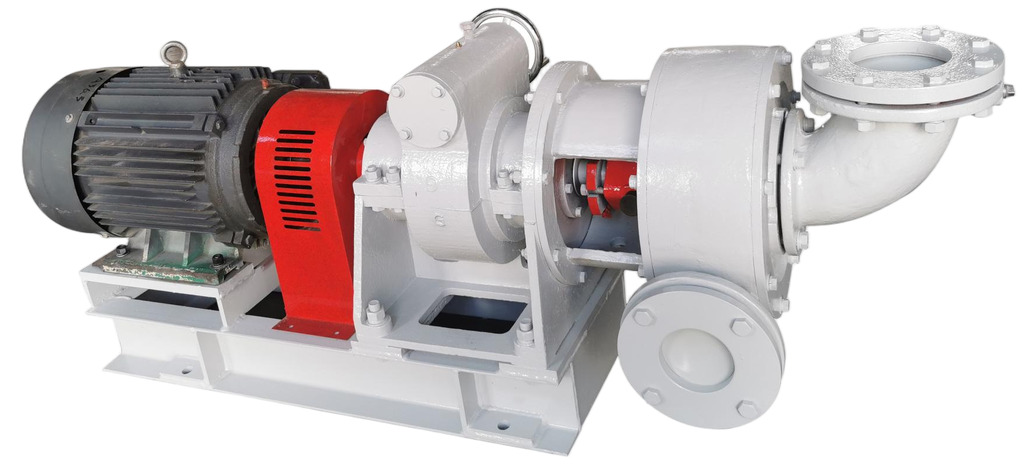

The DML-type grinding device utilizes the material-throwing wheel on the main shaft to fling incoming materials from the feed inlet toward the crushing zone at the center of the grinding disc. Subsequently, relying on the rotation of the disc, the materials are swiftly ground to the required standard as they pass through the coarse and fine grinding zones, before being discharged through the outlet.

The grinding disc is made of high-chromium hard alloy steel, offering a long service life and very high grinding performance. Both, the front and rear bearings can move together with the main shaft within the bearing support structure, providing the necessary space for adjusting the grinding disc clearance and replacing the grinding disc.

This grinding device features a unique structural design and possesses the following core advantages:

High-Efficiency Grinding Capability

Effectively removes large particles and impurities from slurry, preventing cutting damage at the source and ensuring a smooth surface of the green cake. It is also suitable for grinding and recycling waste materials after autoclaving, achieving "dual-purpose functionality in one machine."

Controllable Fineness, Flexible Adjustment

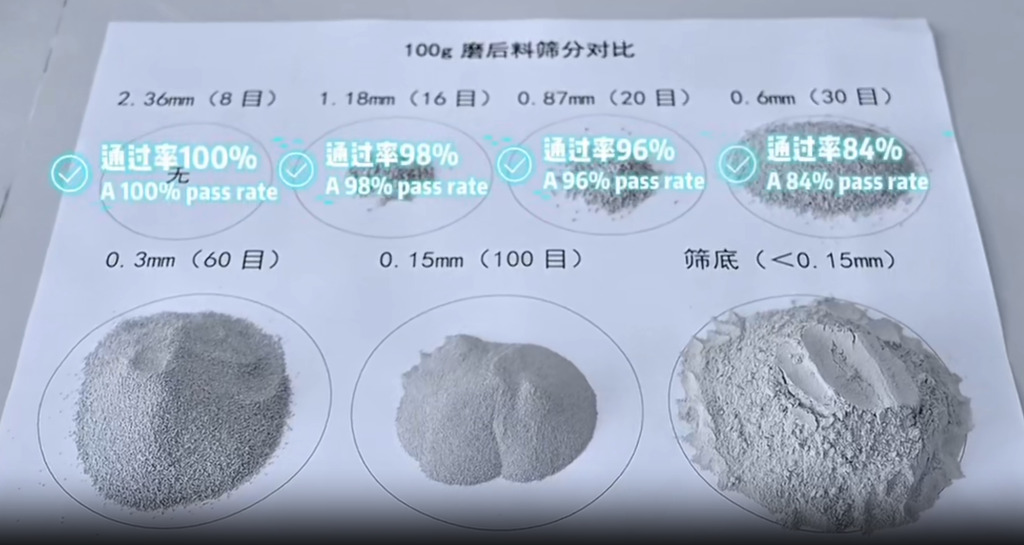

The grinding fineness is very high, with a 96% pass rate for type-20 mesh sieve (0.87mm) particles. Users can easily control the grinding effect by adjusting the disc gap to meet different process requirements.

Wear-Resistant and Durable, Easy Maintenance

The grinding disc is made of alloy material, combining high strength and long-lasting wear resistance. It offers a long service life and is easy to replace, significantly reducing operational and maintenance costs.

Application Scenarios: Addressing Both, Production and Recycling Processes

1. Improve the Surface Quality of Green Cake

The device is installed below the slurry storage tank, allowing the slurry to undergo grinding treatment before entering the forming process, thereby thoroughly removing large particles and impurities. Practical application has verified that this method significantly reduces surface tearing and scratches during the cutting process, consistently raising the product surface quality acceptance rate to over 99%.

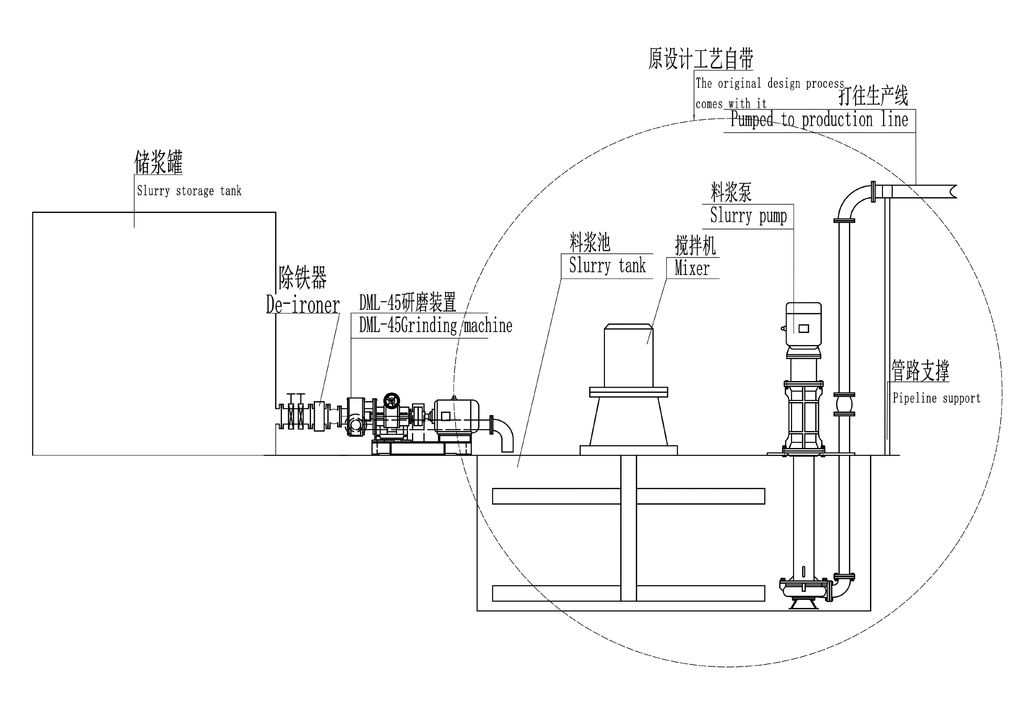

The actual installation case is illustrated in Fig. 3: The slurry from the slurry storage tank passes through the magnetic separator to the grinding device. After grinding, the slurry enters the slurry tank, where it is stirred and then pumped by the slurry pump to the production line.

2. Efficient Waste Recycling

Waste materials from autoclaving are initially crushed and then processed through water-based grinding in this device. The final fineness can be controlled to approximately type-20 mesh sieve, with a pass rate of 96%. The ground waste slurry can be mixed into the raw material slurry at specified ratios for reuse, achieving waste recycling. It is important to control the grinding water volume and waste slurry concentration and adhere to the principle of "grind and use immediately" to avoid long-term soaking that may affect performance. Compared to traditional methods such as ball milling, this device effectively addresses issues such as lightweight waste floating, the need for repeated grinding, and high energy consumption, demonstrating very high efficiency and cost-effectiveness.

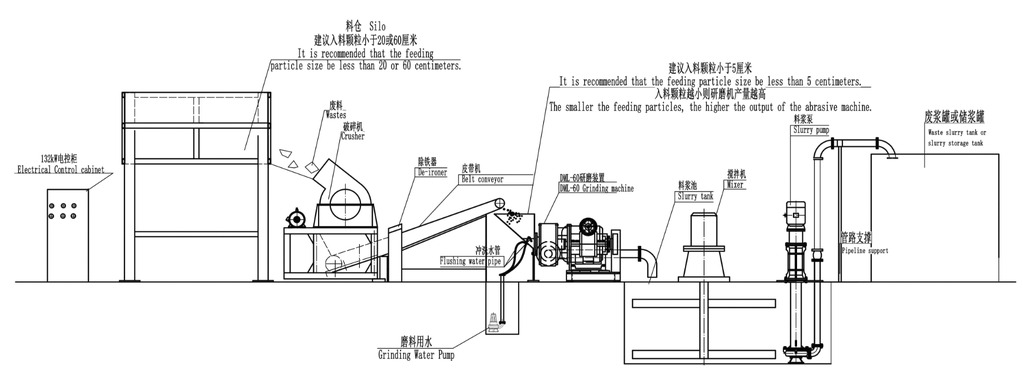

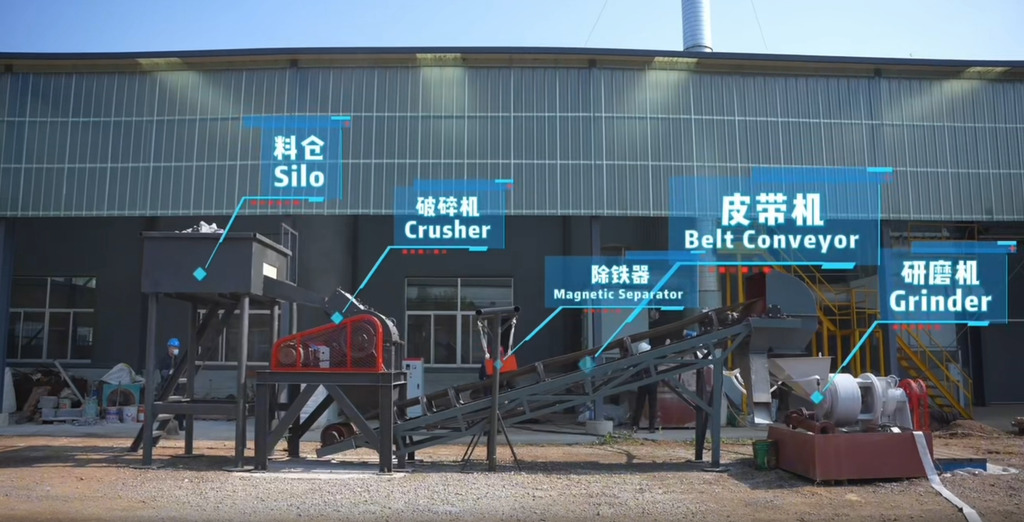

The actual installation case is illustrated in Fig. 4: Waste blocks with a particle size of ≤600mm from the hopper are initially crushed in the crusher to approximately 50mm. They are then conveyed to the grinding device via a belt conveyor. Since waste blocks often contain metal components, a high-strength permanent magnet is installed above the belt conveyor. It can easily attract metal objects even when the material accumulation on the belt reaches 120mm, preventing hard metal debris from entering the grinding device and damaging the high-speed rotating wear-resistant alloy grinding disc. Water intake in the grinding device is controlled by an electric regulating valve, with flushing from multiple locations. The water volume, belt feed speed, and slurry density are linearly monitored and controlled to ensure stable slurry density and consistent particle grinding.

User Data Feedback: Dual Improvements in Efficiency and Quality

According to actual production data, the slurry residue rate after treatment by the grinding device has shown significant improvement:

Table 2: Grinding Device Post-Grinding Slurry Parameter

Post-Grinding Slurry | 45µm Sieve Residue Rate | 80µm Sieve Residue Rate | 0.87mm Sieve Residue Rate |

<64.9% | <44.2% | <4% |

When using manually prepared slurry, the grinding device requires adjustment of the disc gap and control of the water input. The on-site operation time ratio for slurry preparation using the grinding device is 1:3. Manual slurry preparation requires 15 minutes per batch for discharging, whereas incorporating waste slurry using the grinding device takes only 5 minutes. For each batch of manually prepared slurry, the grinding device needs to be stopped for 10 minutes, resulting in significant surplus time available for efficiency optimization.

The particle size distribution (fineness grade) after grinding with the device is more diversified. With the increase in fineness grades and overall fineness, under the same factory conditions with mortar containing 10% waste material processed by two different methods, both, ball milling and the grinding device lead to a 2% increase in mortar consistency. Since product strength is influenced by the water-to-material ratio, the utilization of waste material processed by the grinding device leads to very high final product quality.

Conclusion: Driving Green and High-Quality Development in the Industry

The DML-type grinding device not only provides AAC manufacturers with a reliable technical solution for improving surface quality and recycling waste materials, but also aligns with the current development trends in the building materials industry, which emphasize green and low-carbon initiatives, safety, and efficiency. The widespread adoption of this equipment will help accelerate technological upgrades and the transformation of scientific and technological achievements in the AAC industry, further strengthening the core competitiveness of manufacturers and promoting the sustainable development of the industry toward a resource-saving and environmentally friendly direction.

Dabo Pump believes that, through continuous technological innovation and process optimization, the AAC industry will take more solid strides on the path of high-quality development.

Die vollständige Adresse kannst du dir aus dem letzten Artikel aus 02/2025 nehmen