Science & Innovation

Chemistry and functionality

Soluble oil, a cost saving additive in AAC block manufacturing

Loading...AAC blocks are manufactured using cement, lime, sand or fly ash, water, and a small quantity of aluminum powder/paste. The reaction between aluminum and alkaline slurry produces hydrogen gas, which creates millions of tiny pores that give AAC its lightweight and insulating properties. However, achieving uniform pore distribution and preventing collapse during the green cake stage remains a challenge.

One of the key aids in this process is soluble oil. Despite its name, soluble oil is not a true solution but an oil-in-water emulsion stabilized with surfactants and polymers. Historically used in metalworking fluids, the concept was adopted in AAC plants to stabilize foams, control slurry rheology, and reduce block rejection rates.

This article explains the science behind soluble oils, the role of polymers in stabilizing emulsions, and recent industry trends toward safer and more sustainable additives.

Soluble oil is not actually soluble

“Soluble oil” is really a misnomer: it’s an oil emulsion concentrate designed to disperse in water, not a true molecular solution and stabilized by surfactants and polymers. The milky appearance often leads to the misnomer.

What it actually is

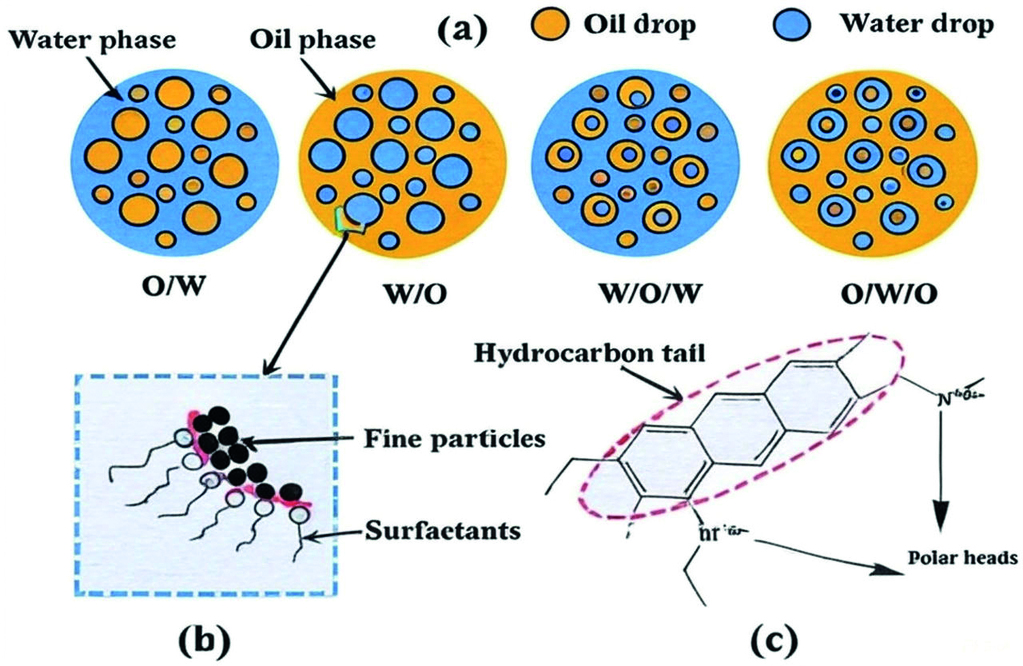

Soluble oil does not exhibit true solubility; the oil molecules are not dissolved at the molecular level as salt or sugar would be. Instead, it is an emulsion in which tiny droplets of oil (typically 0.1–10 µm) are dispersed in water and stabilized by surfactants and polymers acting as emulsifiers. These surfactant molecules possess a hydrophobic tail that prefers oil and a hydrophilic head that prefers water, positioning themselves at the oil–water interface and preventing the droplets from coalescing. The result is a stable, cloudy or milky mixture that only appears to be “dissolved.” Operators typically identify this milky, stable fluid as “oil that dissolves in water,” and the term persists in standards, datasheets, and supplier terminology.

Soluble oil is a liquid admixture miscible in water and designed to suit the different quality of raw materials. During casting or green stage, controlling rate of reaction between various raw materials like quick lime, aluminum powder/paste and silica from sand and cement etc is paramount to the stability of the fresh matrix. Soluble oil acts as a catalyst as well as retarder. It contains a plasticizer or a superplasticizer either a non-surface active polymer or usually a blend of all to improve the bonding of particles and to prevent settling or clumping of light particles available in raw materials like sand, aluminum powder, quick lime etc. It also contains blend of some organic oils and surfactants and polymers to provide strength to cell walls at green stage inside the mass during reaction between solid mass, water and metal powder as well as liberation of hydrogen gas by adjusting the surface tension of mass.

Soluble oil plays a very important role in prevention of shrinkage as it prevents the water separation from the solid mass and also plays important role in controlling the rate of reaction between various reactants like calcium (from cement & lime) and silica (from cement & sand) which results in 1:1 nm tobermorite (Calcium Silicate Hydrate, C-S-H) which is principal final product of AAC.

Chemistry of soluble oils

The following simple diagram shows how surfactant molecules stabilize oil droplets in water, making a stable “soluble oil” emulsion:

· Yellow circles = oil droplets

· Blue heads = hydrophilic (water-loving) ends of surfactant

· Brown tails = hydrophobic (oil-loving) ends anchored in oil

This arrangement prevents droplets from merging, so the oil looks like it has “dissolved” in water.

Component | Representation | Role |

Oil droplet | Yellow sphere | Provides lubrication and stabilization medium |

Surfactant hydrophobic tail | Brown line toward oil | Anchors into oil droplet |

Surfactant hydrophilic head | Blue circle facing water | Stabilizes droplet in water |

Polymer film (PEG, PVA, etc.) | Transparent coating | Prevents coalescence and improves stability |

Table 1: Polymers in soluble oil formulations

Polymer | Function in soluble oil | Effect in AAC slurry |

Polyethylene Glycol (PEG) | Solubility & emulsification | Stabilizes oil droplets, enhances dispersion |

Polyvinyl Alcohol (PVA) | Film-forming, bubble stabilizer | Prevents pore collapse, improves block uniformity |

Polyacrylates | Dispersant, viscosity modifier | Controls rheology, reduces sedimentation |

Carboxymethyl Cellulose (CMC) | Thickening, suspension aid | Improves pore size uniformity |

Hydroxyethyl Cellulose (HEC) | Suspension stability | Prevents segregation in slurry |

Styrene-Maleic Anhydride (SMA) Copolymers | Emulsion stabilizer | Enhances lime/fly ash compatibility |

In practice, blends of these polymers are tailored for each plant’s raw materials and density requirements.

Benefits of soluble oil for AAC production

· Uniform pore structure: Results in consistent density and compressive strength.

· Reduced collapse and segregation: Improves yield and reduces rejections.

· Improved slurry rheology: Enhances lubrication, flowability, pumpability, during the critical foaming and rising stages, and dispersion of cement, lime, and fly ash particles.

· Cost efficiency: Reduction in waste and rejected blocks.

Current trends and future outlook

The AAC industry is witnessing a shift towards sustainable soluble oil formulations:

· Oil-free systems: Fully polymeric stabilizers reduce environmental impact.

· Substitutes for sodium dichromate: Safer alternatives like sodium stannate are gaining adoption.

· Nanotechnology: Potential for nano-stabilizers and advanced polymer systems for precision pore control.

· Bio-based surfactants derived from renewable resources (e.g., APGs), and nano polymer stabilizers are emerging as the next generation of additives. These innovations aim to improve pore control while minimizing environmental impact (ecofriendly).

Conclusion

Although the term is a misnomer, soluble oils are essential for ensuring both the pivotal functions and the stability of AAC block production. By combining oils, surfactants, and polymers, they stabilize the complex slurry environment, ensuring uniform pore formation, improved slurry handling, and reduced rejection rates. Proper polymer selection ensures efficiency, safety, and product quality. With the industry moving toward greener and safer solutions, polymeric stabilizers and bio-based surfactants are set to redefine the next generation of soluble oils for AAC block production. Adoption of these improved formulations can give AAC manufacturers a competitive edge.

Acknowledgment

The author acknowledges information provided by the manufacturers of soluble oil in India.

References

· IS 2185 (Part 3): Autoclaved Aerated Concrete Blocks – Bureau of Indian Standards.

· ASTM C1693 – Standard Specification for AAC.

· Technical datasheets from suppliers: Kuraray (PVA), BASF (polyacrylates), Ashland (cellulose ethers).

· Brochures from soluble oil manufacturers.